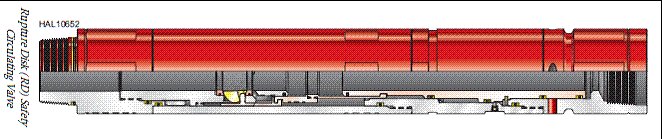

Ceramic rupture disk

Product Parameters

Product Parameters

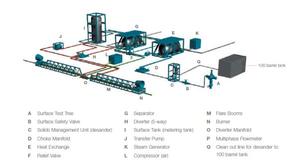

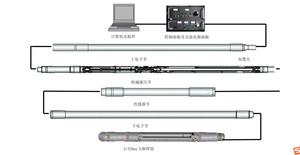

Introduction and Use

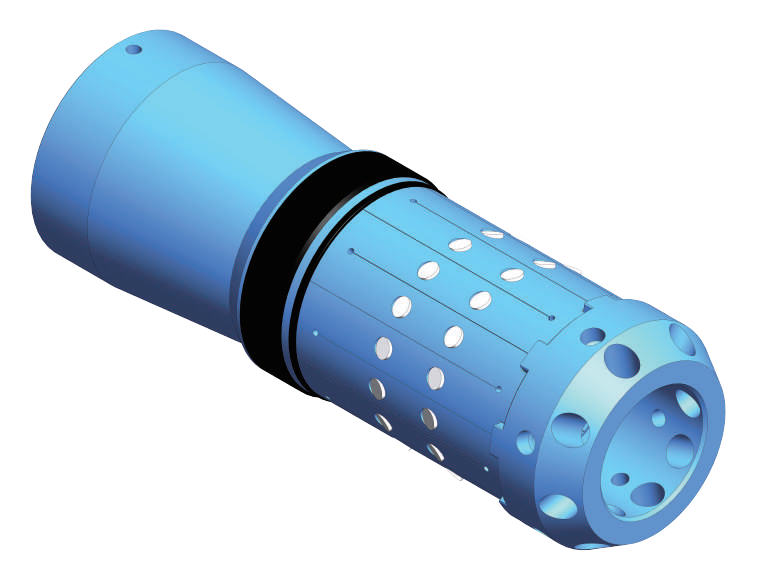

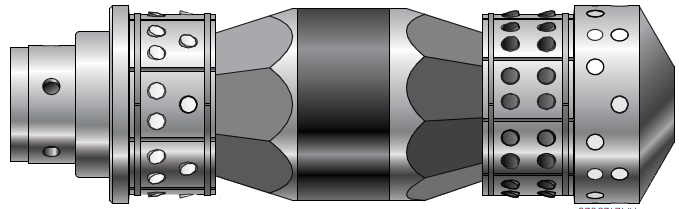

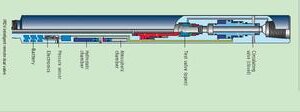

Rupture disks are used to provide well control in temporary wellbore isolation applications such as snubbing in live wells, floating casing and tubing in horizontal sections, and creating underbalance for improved production. A disk can be supplied with a hemispherical geometry for different pressure ratings from above and below. Technical ceramic material made by CoorsTek is also strong in compression, which makes it ideal for a rupture disk application.

CoorsTek technical ceramic rupture disks are made to our customers’ design, leveraging the ceramic material’s compressive strength and other properties for optimized performance. Using CoorsTek’s technical ceramic rupture disks in a completion will lower total cost of operations and reduce non-productive time.

Functions and Features

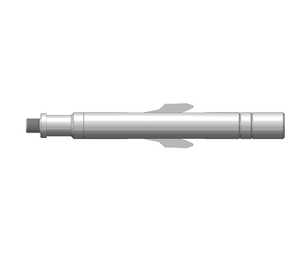

❖ Temporary plugging of the pipe string, for safety and convenience;

❖ High pressure index with stable performance;

❖ Combinations of methods, a wide range of application;

❖ Ceramic materials, high temperature resistance, strong corrosion resistance;

❖ A variety of rupture methods, simple and reliable operation.

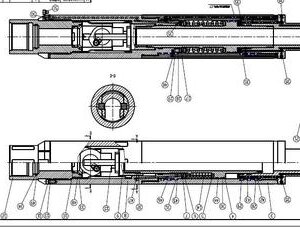

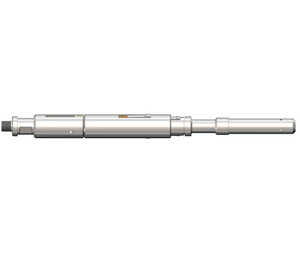

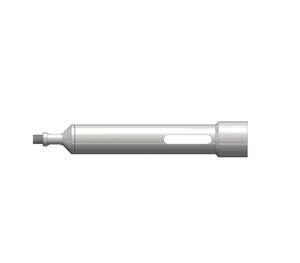

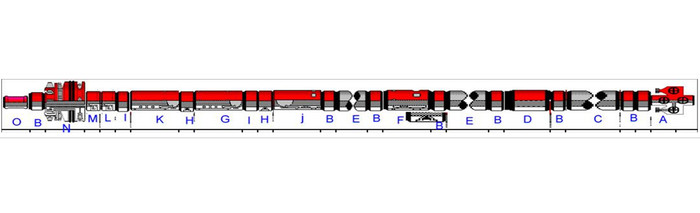

Specifications Parameter Diagram

Specification | External Diameter | Internal Diameter | Working Pressure | Burst Pressure | Working Temperature |

2 3/8 | 62 | 51.1 | 70 | 7-15 | Less than or equal to 150 |

105 | 10-20 | ||||

2 7/8 | 75.4 | 63.7 | 70 | 7-15 | Less than or equal to 150 |

105 | 10-20 |

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559