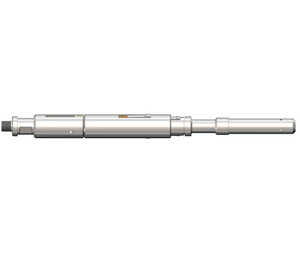

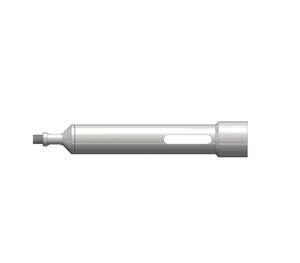

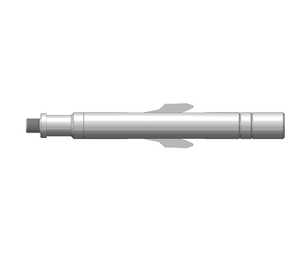

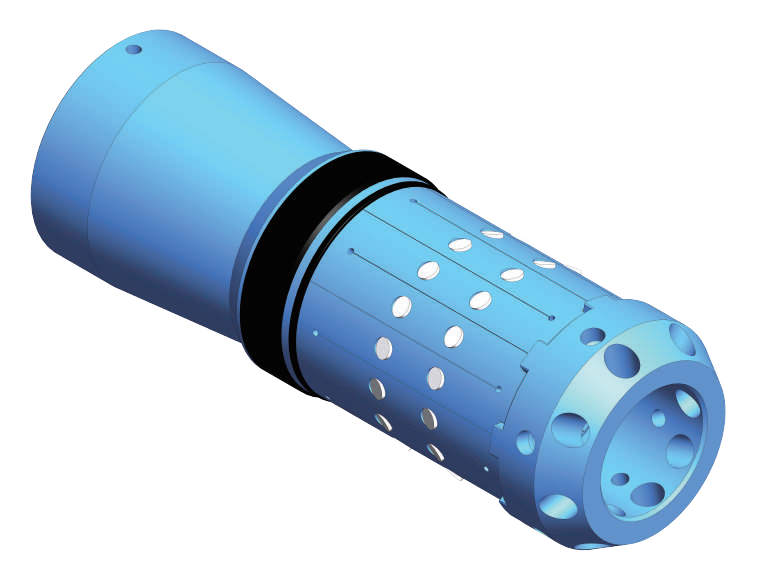

Dissolvable Frac Plug

Product Parameters

Product Parameters

Dissolvable Frac Plug

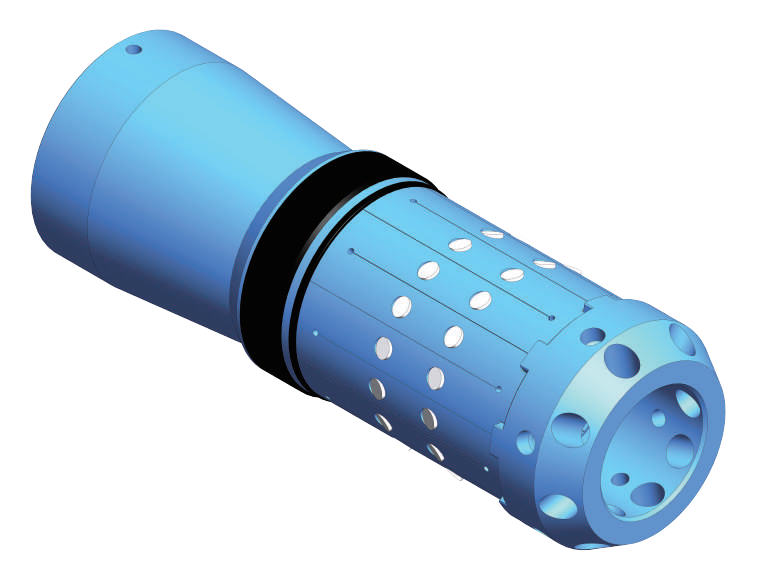

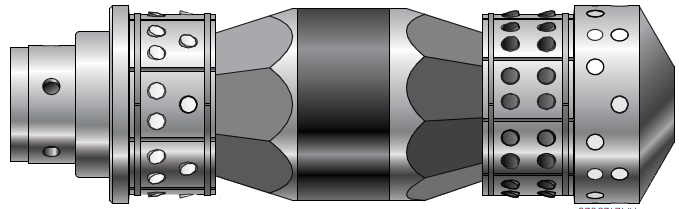

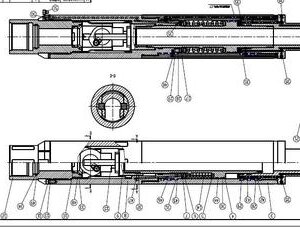

Brief Introduction of Dissolvable Frac Plug Performance

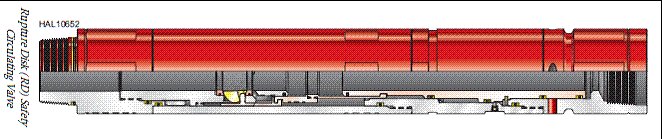

1. The ultra short and large diameter non rubber cylinder structure design can reduce the dissolving mass and improve the dissolving efficiency.

2. The double sealing ring structure of dissolvable metal and dissolvable rubber can make the bridge plug better seal the sleeve and meet the long-term pressure bearing grade of 70MPa.

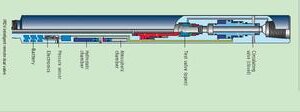

3. It has a series of bridge plugs dissolved in low temperature (30-50 ℃), medium temperature (50-70 ℃), high temperature (80-110 ℃), and ultra-high temperature (120-160 ℃), with a pressure differential grade of 70MPa. According to different construction conditions, users can adjust the dissolution time and temperature to select products.

4. Dissolvable bridge plug dissolved in KCl liquid and clear water. Dissolvable bridge plug can dissolves in 0.05% KCl liquid or even clear water, and can bear pressure difference of 70MPa in 24 hours.

5. In 5-7 days in 1% KCl liquid, the bridge plug is completely dissolved.

6. The unique pull rod design can better lock the guide shoes and prevent the bridge plug from setting in advance in the process of entering the well.

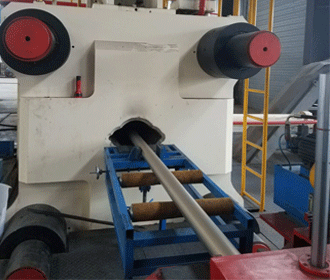

7. Running with Baker#20/10 standard wireline or hydraulic setting tools.

8. It is suitable for P110 and BG125v steel casing with high steel grade .

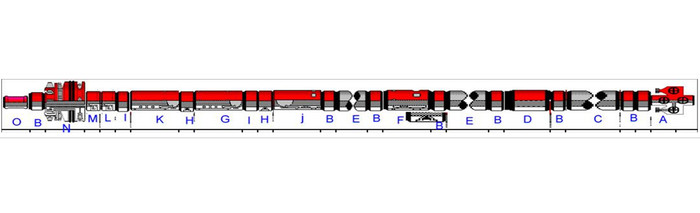

Performance Parameters of Dissolvable Frac Plug | |||||||

Specification | KING-68 | KING-89.5 | KING-91 | KING-98 | KING-100 | KING-104 | KING-111 |

Size | 3.5" | 4.5" | 4.5" | 5" | 5" | 5.5" | 5.5" |

OD | 2.677" | 3.523" | 3.582" | 3.858" | 3.937" | 4.094" | 4.37" |

ID | 1.1" | 1.7" | 1.7" | 1.89" | 2" | 2.165" | 2.365" |

Length | 9.5" | 10" | 10" | 12.2" | 11.4" | 11.35" | 11.15" |

Casing pound scale | 9.2# | 13.5-15.1# | 11.6# | 13# | 13-15# | 23-26# | 17-20# |

Setting force | 9-10T | 12-14T | 12-14T | 16T | 16T | 16T | 16T |

Differential pressure rating | 8000psi | 10000psi | 10000psi | 10000psi | 10000psi | 10000psi | 10000psi |

Dissolvable ball | 1.375" | 2" | 2" | 2.28" | 2.28" | 2.55" | 2.67" |

Operation temperature | 75-300℉ | 75-300℉ | 75-300℉ | 75-300℉ | 75-300℉ | 75-300℉ | 75-300℉ |

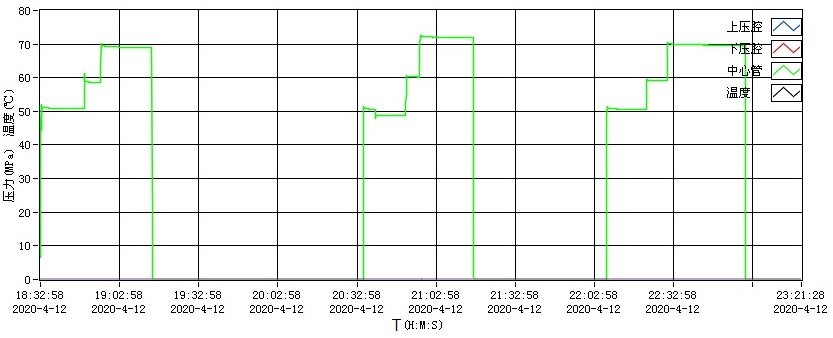

Pressure Curve

KW-A Dissolvable Ball | ||

|---|---|---|

| Material: | Magnesium Alloy |  |

| Density: | 2.6-2.7g/cm3 | |

| Pressure grade: | 10000psi | |

| Dissolve medium: | fresh water | |

| Size: | 0.875"-5.000" | |

| Dissolve data: | At 80- 150℉ fresh water,HS-A dissolvable ball doesn’t dissolve in the first 3-5hrs, and the complete dissolving time is 30-100hrs. | |

| At 200℉ fresh water,HS-A dissolvable ball doesn’t dissolve in the first 6hrs (coating),and the complete dissolving time is 20-40hrs. | ||

KW-B Dissolvable Ball | ||

|---|---|---|

| Material: | Magnesium Alloy |  |

| Density: | 1.8-1.9g/cm3 | |

| Pressure grade: | Pressure grade | |

| Dissolve medium: | 3%KCL | |

| Size: | 0.875"-5.000" | |

| Dissolve data: | Ball dissolves 0.9-1.1mm/h in diameter at 200℉ , 3%KCL solution. | |

| Ball dissolves 0.4-0.5mm/h in diameter at 150℉ , 3%KCL solution. | ||

| HS-C Dissolvable Ball | ||

|---|---|---|

| Material: | Magnesium Alloy |  |

| Density: | 1.8-1.9g/cm3 | |

| Pressure grade: | 10000psi | |

| Dissolve medium: | 3%KCL | |

| Size: | 0.875"-5.000" | |

| Dissolving data: | Ball dissolves 1.5mm/h in diameter at 200℉, 3%KCL solution. | |

| Ball dissolves 0.84mm/h in diameter at 150℉ , 3%KCL solution. | ||

| HS-D Dissolvable Ball | ||

| Material: | magnesium aluminum alloy |  |

| Density: | 1.8-1.9g/cm3 | |

| Pressure grade: | 10000psi | |

| Dissolving medium: | 3%KCL | |

| Size: | 0.875"-5.000" | |

| Dissolving data: | Ball dissolves 3.0mm/h in diameter at 200℉ , 3%KCL solution. | |

| Ball dissolves 2.0mm/h in diameter at 200℉ , 0.05%KCL solution. | ||

| Ball dissolves 1.8mm/h in diameter at 150℉ , 3%KCL solution. | ||

| Ball dissolves 0.6mm/h in diameter at 150℉ , 0.05%KCL solution. | ||

KW-E Dissolvable Ball | ||

|---|---|---|

| Material: | Magnesium Alloy |  |

| Density: | 1.8-1.9g/cm3 | |

| Pressure grade: | 10000psi | |

| Dissolve medium: | 3-8%KCL | |

| Size: | 0.875"-5.000" | |

| Dissolve data: | At 1-8%KCL of 200℉solution,HS-D dissolvable ball doesn’t dissolve in the first 6hrs,and the complete dissolving time is 40-60hrs. | |

KW-F Dissolvable Ball | ||

|---|---|---|

| Material: | Magnesium Alloy |  |

| Density: | 1.8-1.85g/cm3 | |

| Pressure grade: | 10000psi | |

| Dissolve medium: | 20%HCL | |

| Size: | 0.875"-5.000" | |

| Dissolve data: | At 20%HCL of 150℉ solution,HS-E dissolvable ball doesn’t dissolve in the first 5hrs,and the complete dissolving time is 20-30hrs. | |

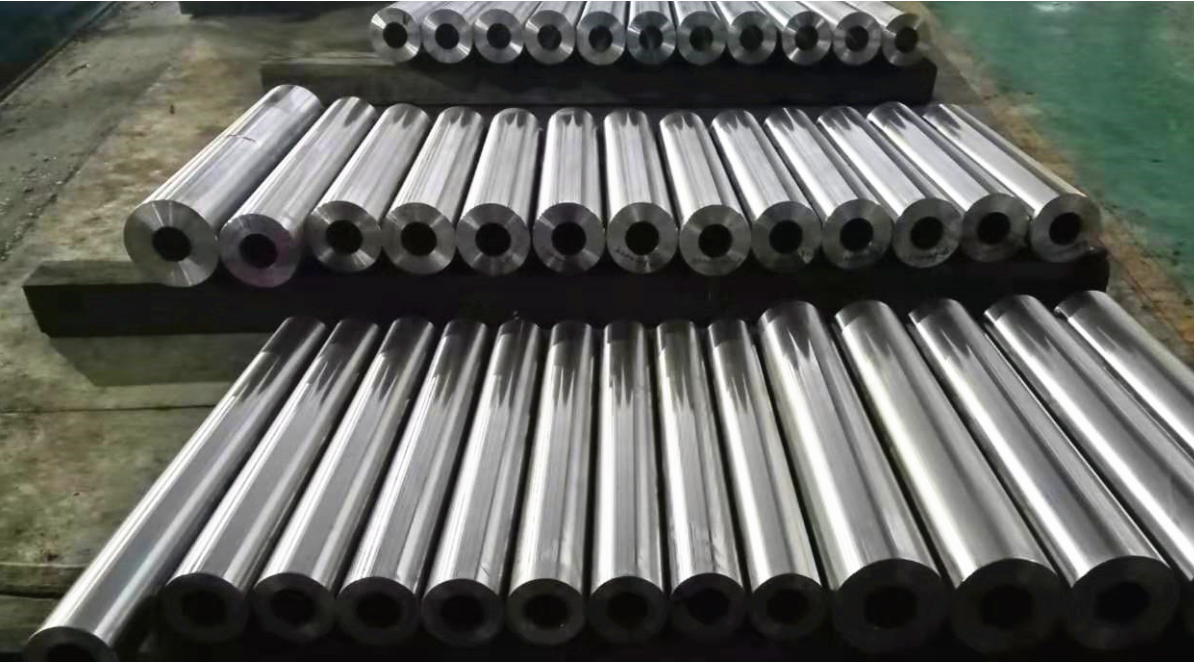

| HS-M100 Dissolvable Bar | |

|---|---|

| Material: | Magnesium Alloy |

| Density: | 1.8-1.9g/cm3 |

| Tensile strength: | 330MPa |

| Yield strength: | 230MPa |

| Elongation: | 6-8% |

| Dissolving data: | 70-90mg/cm2/hr ( 200℉, 3%KCL ) |

| 40-50mg/cm2/hr ( 150℉, 3%KCL ) | |

| HS-M100-1 Dissolvable Bar | |

|---|---|

| Material: | Magnesium Alloy |

| Density: | 1.8-1.9g/cm3 |

| Tensile strength: | 370MPa |

| Yield strength: | 260MPa |

| Elongation: | 3% |

| Dissolving data: | 60-70mg/cm2/hr ( 200℉, 3%KCL ) |

| 30-40mg/cm2/hr ( 150℉, 3%KCL ) | |

| HS-M200 Dissolvable Bar | ||

|---|---|---|

| Material: | Magnesium Alloy |  |

| Density: | 1.9-2.0g/cm3 | |

| Tensile strength: | 420MPa | |

| Yield strength: | 310MPa | |

| Elongation: | 5-6% | |

| Dissolving data: | 40-50mg/cm2/hr ( 200℉, 3%KCL ) | |

| 20-30mg/cm2/hr ( 150℉, 3%KCL ) | ||

| HS-M400 Dissolvable Bar | |

|---|---|

| Material: | Magnesium Alloy |

| Density: | 1.8-1.9g/cm3 |

| Tensile strength: | 280MPa |

| Yield strength: | 190MPa |

| Elongation: | 11-15% |

| Dissolving data: | 40-50mg/cm2/hr ( 200℉, 3%KCL ) |

| HS-M400-1 Dissolvable Bar | |

|---|---|

| Material: | Magnesium Alloy |

| Density: | 1.8-1.9g/cm3 |

| Tensile strength: | 280MPa |

| Yield strength: | 190MPa |

| Elongation: | 25-32% |

| Dissolving data: | 20-30mg/cm2/hr ( 200℉, 3%KCL ) |

| HS-M500 Dissolvable Bar | ||

|---|---|---|

| Material: | Magnesium Alloy | |

| Density: | 1.8-1.9g/cm3 | |

| Tensile strength: | 230MPa | |

| Yield strength: | 180MPa | |

| Elongation: | 11-15% | |

| Dissolving data: | 150-170mg/cm2/hr ( 200℉, 3%KCL ) | |

| 50-70mg/cm2/hr ( 150℉, 3%KCL ) | ||

| HS-M600 Dissolvable Bar | ||

|---|---|---|

| Material: | Magnesium Alloy |  |

| Density: | 1.8-1.9g/cm3 | |

| Tensile strength: | 260MPa | |

| Yield strength: | 220MPa | |

| Elongation: | 8-10% | |

| Dissolving data: | 280-300mg/cm2/hr ( 200℉, 3%KCL ) | |

| 150-170mg/cm2/hr ( 150℉, 3%KCL ) | ||

| 30-40mg/cm2/hr ( 200℉, freshwater ) | ||

| HS-M600-1 Dissolvable Bar | ||

|---|---|---|

| Material: | Magnesium Alloy | |

| Density: | 1.9-2.0g/cm3 | |

| Tensile strength: | 300MPa | |

| Yield strength: | 260MPa | |

| Elongation: | 5-6% | |

| Dissolving data: | 350-380mg/cm2/hr ( 200℉, 3%KCL ) | |

| 200-230mg/cm2/hr ( 150℉, 3%KCL ) | ||

| 40-60mg/cm2/hr ( 100℉, 0.05%KCL ) | ||

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559