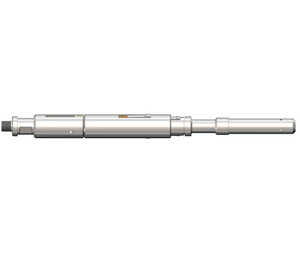

Champ packer

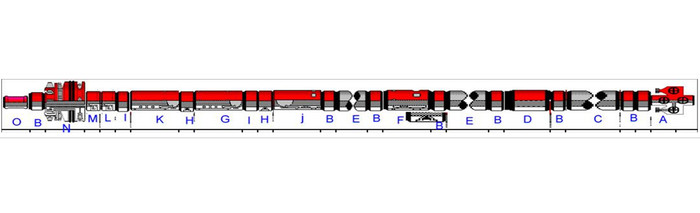

Product Parameters

Product Parameters

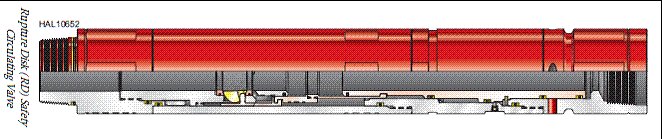

Briefly Introduce:

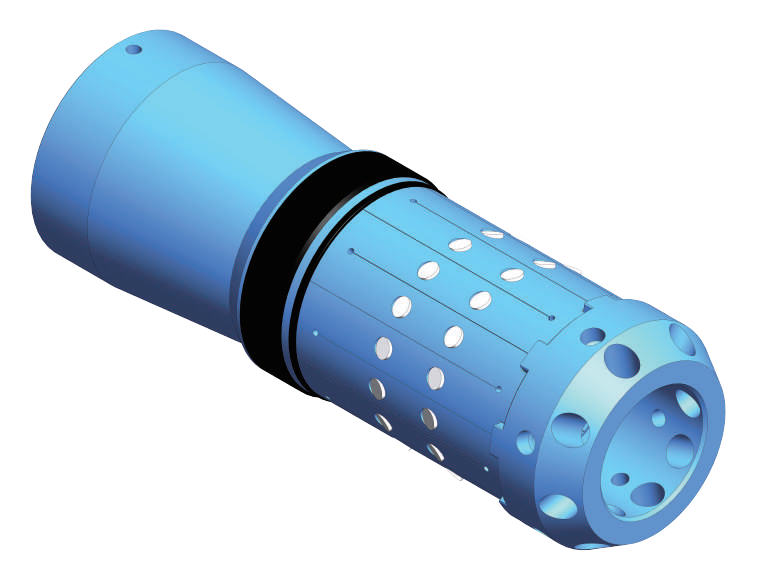

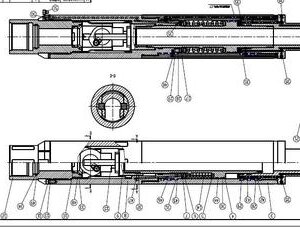

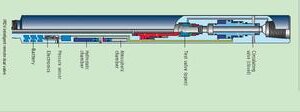

The CHAMP IVpacker is a hookwall-retrievable packer with a concentric bypass. As the tool is lowered into the hole,

a J-slot holds the bypass open and controls the setting of the packer. When the packer is set, a balancing piston activated by tubing pressure holds the bypass closed.

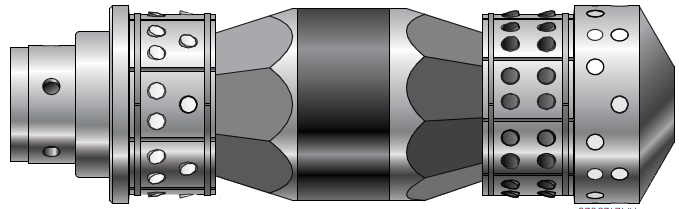

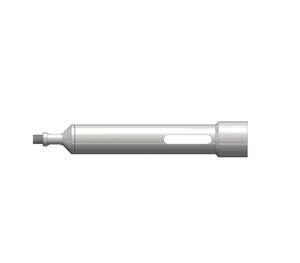

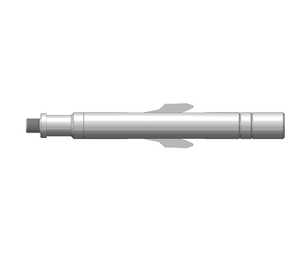

Each tool assembly includes a J-slot mechanism, mechanical slips, packer elements, hydraulic slips, and a bypass. Round, piston-like slips used in the hydraulic holddown mechanism prevent the tool from being pumped up the hole. The bypass allows fluids to pass around the bottom of the tool when it is removed from the hole. This design eliminates accidentally openingconventional bypass during circulation around the bottom of the packer.

Circulation around the CHAMP IV packer is not interrupted if the packer element temporarily seals unintentionally as when it passes through points of interference in the casing.

The CHAMP IV packer is well suited to tubing conveyed perforating applications where the firing head assembly is easily incorporated into the CHAMP IV packer. The CHAMP IV packer is ideally suited for horizontal applications due to its limited rotational requirements and integrated circulating valve. Just a quarter-turn is required, at the tool, to set the packer and close the circulating valve. A straight upward pull opens the circulating valve and unseats

the packer.

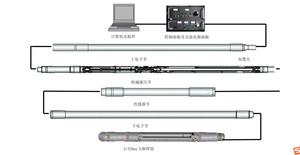

Features and Benefits

• The packer is used in highly deviated wells or where pipe manipulation is difficult.

• Picking the packer straight up (no torque required) opens the bypass.

• The tool is easily relocated in multiple zones during a single trip for treating, testing, or squeezing.

• The concentric bypass valve allows a larger bypass flow area.

• The CHAMP IV packer is used with a retrievable bridge plug for straddling zones during various operations.

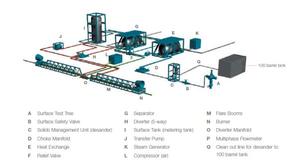

• A CHAMP IV packer would be the tool of choice where positive circulation below the packer is required such as

in drillstem testing, TCP applications, using tailpipe, for shallow service, and as liner tools.

Operation

The tool is run slightly below the necessary setting position. If the packer is to be set, it must be picked up, and right-hand rotation must be applied so that a half-turn can be obtained at the tool. In deep or deviated holes, several turns with the rotary may be necessary. For the position to be maintained, the right-hand torque must be held until the mechanical slips on the tool are set and can begin taking weight.

Pressure applied below the packer forces the hydraulic holddown slips against the casing to prevent the packer from being pumped up the hole.

The concentric bypass valve is balanced to the tubing surface pressure, which prevents the bypass from being pumped open with tubing pressure. Straight, upward pull on the tubing string opens the bypass and unsets the packer.

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559