Permanent Packers

Product Parameters

Product Parameters

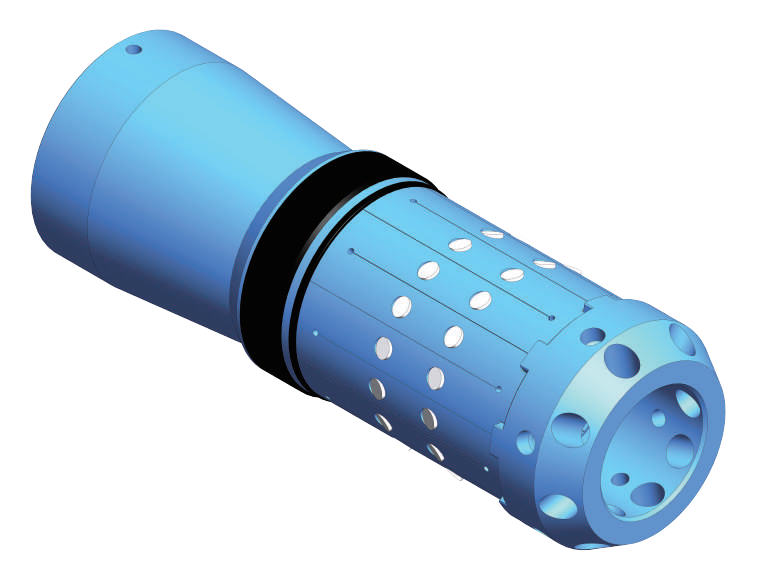

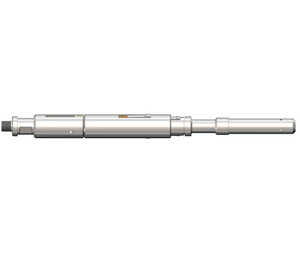

PERMAPAK PACKER - SINGLE BORE

The Permapak Seal Bore Packer can be used for single or multiple zone completions. It is designed for wells where high pressure/temperatures and corrosive fluids are present and it is available in a variety of elastomers and seal bore materials to meet a wide range of hostile downhole environments. This packer is recommended for injection stimulation and testing or can become a temporary bridge plug when used with our knock-out or pump-out bottom assembly (refer to Permapak Packer Tubing and Accessories product sheet). The Permapak Seal Bore Packer comes with a complete line of tubing seal accessories and elastomers.

Special Features

Electric line, hydraulic or mechanical set

Components keyed for milling

Anti-extrusion rings expand to casing ID to prevent rubber extrusion

Full circle slips allow for faster run time

Product Specifications - Single Bore

Casing | Recommended Hole Size (inches) | Tool OD (inches) | Packer Bore (inches) | Min ID Thru Seals (inches) | |||

Size | Weight (lbs/ft) | ||||||

3-1/2 | 7.7 - 10.2 | 2.922 - 3.068 | 2.750 | 1.750 | 1.187 | ||

4 | 9.5 - 11.6 | 3.428 - 3.548 | 3.281 | 1.750 | 1.187 | ||

11.6 - 14.8 | 3.240 - 3.428 | 3.090 | 1.750 | 1.187 | |||

4-1/2 | 9.5 - 13.5 | 3.920 - 4.090 | 3.750 | 2.500 | 1.910 | ||

2.688 | 1.938 | ||||||

15.1 | 3.826 | 3.600 | 2.500 | 1.910 | |||

5 | 15.0 - 21.4 | 4.126 - 4.408 | 3.968 | 2.500 | 1.910 | ||

2.688 | 1.938 | ||||||

5-1/2 | 13.0 - 17.0 | 4.892 - 5.044 | 4.532 | 2.688 | 1.938 | ||

3.000 | 2.375 | ||||||

17.0 - 23.0 | 4.670 - 4.892 | 4.438 | 2.688 | 1.938 | |||

3.000 | 2.375 | ||||||

23.0 - 26.0 | 4.548 - 4.670 | 4.250 | 2.688 | 1.938 | |||

6 | 18.0 - 26.0 | 5.132 - 5.424 | 4.875 | 3.000 | 2.375 | ||

6-5/8 | 17.0 - 32.0 | 5.675 - 6.135 | 5.468 | 3.250 | 2.416 | ||

7 | 17.0 - 23.0 | 6.366 - 6.538 | 6.000 | 3.250 | 2.406 | ||

4.000 | 3.000 | ||||||

23.0 - 32.0 | 6.094 - 6.366 | 5.813 | 3.250 | 2.406 | |||

4.000 | 3.000 | ||||||

32.0 - 38.0 | 5.920 - 6.094 | 5.625 | 3.250 | 2.406 | |||

4.000 | 3.000 | ||||||

7-5/8 | 24.0 - 39.0 | 6.625 - 7.025 | 6.250 | 3.250 | 2.416 | ||

4.000 | 3.000 | ||||||

8-5/8 | 24.0 - 32.0 | 7.921 - 8.097 | 7.625 | 4.000 | 3.000 | ||

5.250 | 4.250 | ||||||

9-5/8 | 36.0 - 53.5 | 8.535 - 8.921 | 8.125 | 3.250 | 2.416 | ||

4.000 | 3.000 | ||||||

4.750 | 3.500 | ||||||

6.000 | 4.750 | ||||||

10-3/4 | 40.5 - 55.5 | 9.760 - 10.050 | 9.496 | 4.000 | 3.000 | ||

9.300 | 6.000 | 4.750 | |||||

45.5 - 60.7 | 9.660 - 9.950 | 9.300 | 4.000 | 3.000 | |||

11-3/4 | 42.0 - 65.0 | 10.682 - 11.084 | 10.430 | 6.000 | 4.750 | ||

13-3/8 | 54.5 - 77.0 | 12.275 - 12.615 | 12.000 | 9.000 | 8.000 | ||

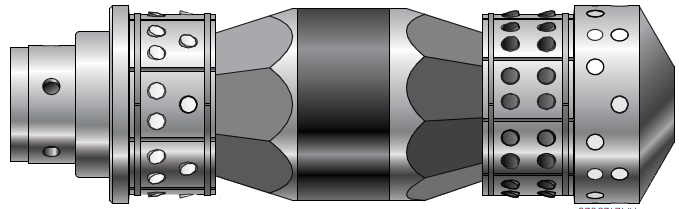

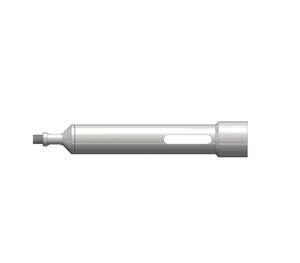

PERMAPAK PACKER - DUAL BORE

The Dual Bore Permapak Packer is a highly versatile packer which has a large upper sealbore to allow for a large bore through the packer. This packer may be set on wireline or hydraulically and can be used for single or multiple zone completions. This packer is designed for wells where high flow rates, high pressure, high temperatures and corrosive fluids are present. This packer is available in a variety of elastomers and seal bore materials to meet a wide range of hostile downhole environments. This packer is recommended for production, injection, stimulation and testing or can become a temporary plug when used with the Knock-Out or Pump-Out Bottom Assembly.

The Dual Bore Permapak Packer comes with a complete line of accessories and elastomers. Contact D&L sales for more information.

Special Features

Large packer through bore

Large seal mandrel through bore

Proven Permapak Packer design

Product Specifications

Casing | Recommended Hole Size (inches) | Tool OD (inches) |

Seal Bore | Min ID Thru Seals (inches) | ||

Size (inches) | Weight (lbs/ft) | Upper (inches) | Lower (inches) | |||

4 | 9.5 - 11.6 | 3.428 - 3.548 | 3.281 | 2.688 | 1.750 | 1.750 |

11.6 - 14.8 | 3.240 - 3.428 | 3.090 | 2.688 | 1.750 | 1.750 | |

5 | 15.0 - 21.0 | 4.154 - 4.408 | 3.968 | 3.000 | 2.688 | 2.375 |

5-1/2 | 23.0 - 26.0 | 4.548 - 4.670 | 4.250 | 3.000 | 2.688 | 2.375 |

7 | 23.0 - 32.0 | 6.094 - 6.366 | 5.813 | 4.750 | 4.000 | 3.500 |

26.0 - 29.0 | 6.184 - 6.276 | 5.900 | 5.250 | 4.375 | 4.250 | |

7-5/8 | 24.0 - 39.0 | 6.625 - 7.025 | 6.250 | 5.250 | 4.000 | 4.250 |

9-5/8 | 36.0 - 53.5 | 8.535 - 8.921 | 8.125 | 7.000 | 6.000 | 4.750 |

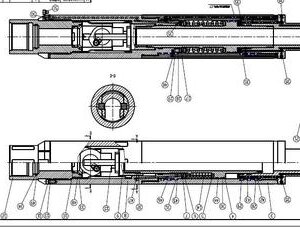

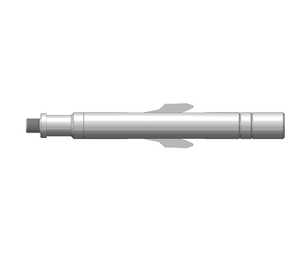

HYDRAULIC PERMAPAK PACKER

The Hydraulic Permapak Packer is a hydraulic set seal bore packer and is the hydraulic set equivalent of the Permapak Seal Bore Packer. The full range of Permapak Seal Bore Accessories may be used with the Hydraulic Permapak.

Pressure sets the packer via a setting chamber built into the tool. Pressure enters the setting chamber via holes in the polished bore of this packer. These holes can be isolated with a ball-operated sub so other hydraulic operated tools can be functioned before setting the packer.

Special Features

Uses proven Permapak components

Compatible with Permapak options

Optional upper sealbore available

Single bore or dual bore option

Product Specifications - Single Bore

Casing | Recommended Hole Size (inches) | Tool OD (inches) | Packer Bore (inches) | Min ID Thru Seals (inches) | |

Size (inches) | Weight (lbs/ft) | ||||

7 | 23.0 - 32.0 | 6.094 - 6.366 | 5.875 | 4.000 | 3.000 |

32.0 - 38.0 | 5.920 - 6.094 | 5.813 | 4.000 | 3.000 | |

9-5/8 | 36.0 - 53.5 | 8.535 - 8.921 |

8.125 | 4.750 | 3.500 |

5.000 | 4.750 | ||||

Product Specifications - Dual Bore

Casing | Recommended Hole Size (inches) | Tool OD (inches) | Seal Bore | Min ID Thru Seals (inches) | ||

Size (inches) | Weight (lbs/ft) | Upper (inches) | Lower (inches) | |||

7 | 17.0 - 23.0 | 6.366 - 6.538 | 6.000 | 5.250 | 4.000 | 4.000 |

23.0 - 32.0 | 6.094 - 6.366 | 5.875 | 5.250 | 4.000 | 4.000 | |

9-5/8 | 36.0 - 53.5 | 8.535 - 8.921 | 8.250 | 7.500 | 6.000 | 6.000 |

PERMAPAK ACCESSORIES

Seal Bore Extension

A Seal Bore Extension is used in installations where floating seals are required due to tubing contractions. This packer accessory allows for a continuous seal bore and is available in lengths up to twenty feet.

Seal Bore to Mill-Out Coupling

A Seal Bore to Mill-Out Coupling is used to connect mill out extensions to seal bore extensions.

Concentric Bottom

A Concentric Bottom is used to connect a seal bore extension to a pac ker.

Knock-Out Plug Bottom

When a Knock-Out Bottom is run below the packer, the knock-out plug allows a packer to serve as a bridge plug holding pressure from above and below.

Knock-Out Plug

A Knock-Out Plug is knocked out when the production string is landed.

Mill-Out Extension

A Mill-Out Extension is used in installations where floating seals are required due to tubing contractions. In addition, this packer accessory provides a larger ID between a packer bore and a seal bore extension allowing a packer plucker when a packer is milled out.

Pump Out Plug

A Pump-Out Plug is available with a choice of threads allowing the pump-out plug to be attached to a packer, seal bore extension, mill-out extension or tailpipe and hold pressure from below after the packer is set. Once the production string is landed, pressure is applied to the tubing and the pump-out plug is removed to allow full opening.

Mill-Out Bottom

A Mill-Out Bottom is used to connect a mill-out extension to a packer.

Concentric Coupling

A Concentric Coupling is used to connect seal bore extensions to increase length.

Wireline Re-Entry Bottom

A Wireline Re-Entry Bottom is used as the packer bottom when an extension below a packer is not required.

Anchor Latch Assembly

The Anchor Latch Seal Assembly is used when floating seals are not required. This assembly allows the tubing string to be in tension or compression. Upon set down the anchor latches into the packer and can be removed with eight to ten right-hand turns.

Seal Unit

The standard Seal Unit i s furnished with bonded nitrile rings and a 12-inch make-up length. These units may be ordered in various lengths and with severe service seal rings for high temperature and corrosive environmental conditions.

Half Mule Shoe Guide

The Half Mule Shoe Guide is standard with the Seal Assembly to allow for easy entry into the packer bore.

Snap Latch Assembly

The Snap Latch Seal Assembly latches into the packer upon set down (like our Anchor Latch Seal Assembly). It can be removed with straight pull of 10,000 to 12,000 lbs. above tubing weight. The Snap Latch Seal Assembly is used where a mechanical indication is required to verify the seal assembly is properly positioned in the packer bore.

Locator Seal Assembly

The Locator Seal Assembly is used in installations which require floating seals. Once landed, the seal locator prevents downward movement of the tubing while allowing the seal to move with tubing contraction.

WIRELINE ADAPTER KIT – FOR PERMAPAK PACKER

The Wireline Adapter Kit (WLAK) – for Permapak Packer is designed to set Permapak Seal Bore Packers with industry standard wireline pressure setting assemblies or comparable equipment.

This setting equipment can also be used with hydraulic setting tools that are configured like the standard setting tool. The setting equipment is designed so the outer sleeve can be adjusted to provide a proper make up to the packer.

Product Specifications

Setting Tool Size | Setting Tool OD (inches) | External Threads | Internal Threads | Packer Sizes |

05 | 1.718 | 1-1/4” UNS | 5/8” UNF | 2-3/8” 2-7/8” 3-1/2” |

10 | 2.750 | 2-1/2” ACME | 1” UNC | 4” 4-1/2” 5” |

20 | 3.800 | 3-1/2” STUB ACME | 2” ACME | 5-1/2” & LARGER |

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559