Service Tools

Product Parameters

Product Parameters

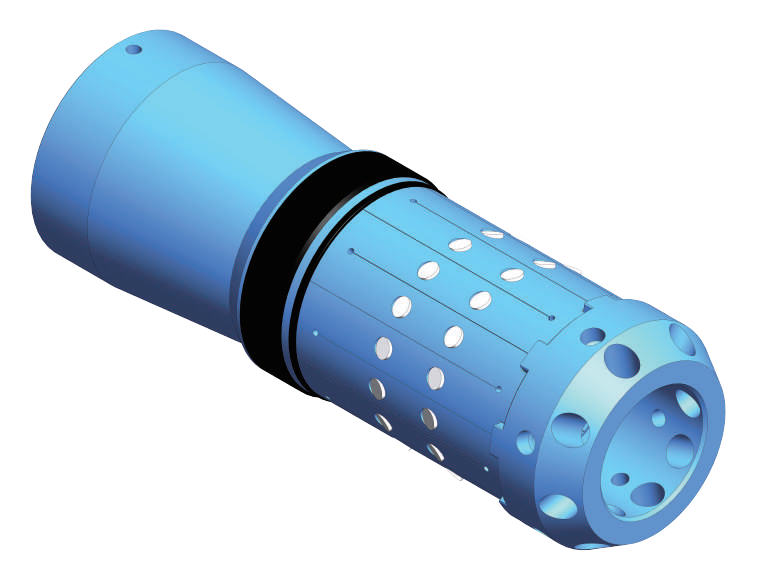

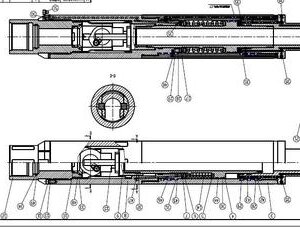

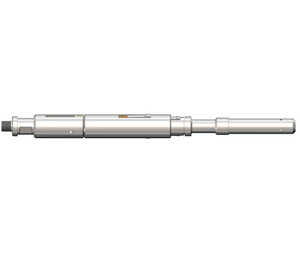

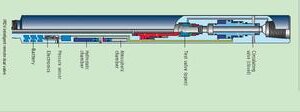

MODEL “H” HYDRAULIC SETTING TOOL

The Model “H” Hydraulic Setting Assembly (HST) is a

hydraulic setting tool designed for setting packers and plugs without pipe manipulations. It is used to set packers and plugs that are normally set with a Model “E-4” Wireline Pressure Setting Assembly (or similar wireline setting equipment). The same adapter kit that is used on wireline can be used with the Model “H” HST.

The Model “H” HST and packer (or plug) is run in on the tubing to the desired setting depth and a ball is dropped to the HST. Pressure is applied to close the fill ports, which also opens the setting pistons to pressure. As pressure is applied, force is transmitted to the packer (or plug) to set. Tubing tension can also be applied to supplement the setting force generated by the pressure applied.

The standard setting tool comes with three pistons, but additional pistons can be added to reduce setting pressure.

Special Features

Large internal by-pass

Tubing fills automatically as HST is run in the hole

Premature setting is prevented by means of a shear screw in the cross link sleeve

Ported top sub permits circulation through the HST

Use existing wireline adapter kits

Product Specifications

Size (inches) | Tool Max PSI | Max Pull (lbs) | Tool OD (inches) | Total Effective Piston Area (in2) | Connection | |

Top | Bottom (Baker E-4) | |||||

#05 | 10,000 | 31,000 | 1.718 | 1.49 | 1.315 EUE | SIZE 05 |

#10 | 10,000 | 75,000 | 2.750 | 3.44 | 1.900 EUE | SIZE 10 |

6.88 | 1.900 NUE | SIZE 10 | ||||

#20 | 6,000 | 120,000 | 3.81 | 13.980 | 2-3/8 EUE | SIZE 20 |

4,000 | 120,000 | 3.81 | 20.940 | 2-3/8 EUE | SIZE 20 | |

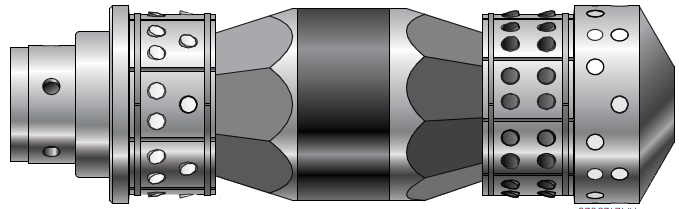

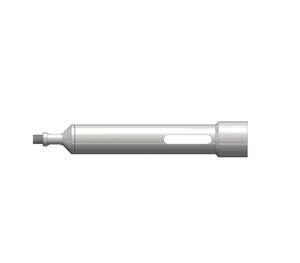

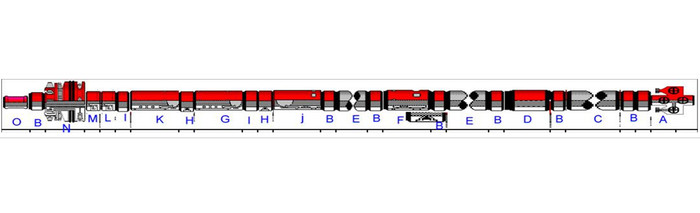

LC HYDRAULIC SETTING TOOL

The LC Hydraulic Setting Tool (HST) is used to set packers and plugs on tubing that are normally set on wireline. This allows setting in high-angle wells or deviated wells where it is difficult to use wireline equipment. The LC HST allows for packers and plugs to be set with a combination of hydraulic and mechanical forces. This can reduce the setting pressure needed by supplementing the set with tubing tension. A single size LC HST may be used to set a multitude of packer sizes by simply attaching the proper size LC Hydraulic Adapter Kit.

Special Features

Heavy-duty design

Multiple setting chambers for lower setting pressures

Operable in heavy mud systems

Can be equipped to operate in high temperatures

Circulation through the tool during run in

Product Specifications

Tool | Setting Area (in2/Cylinder) | Tool OD (inches) | Tool ID (inches) | Thread Connection Box Up / Pin Down |

LC-15 | 4.70 | 3.718 | 1.50 | 2-7/8 EUE |

LC-20 | 4.60 | 4.375 | 2.00 | 3-1/2 IF TOOL JOINT |

LC-20HD | 4.60 | 4.375 | 1.75 | 3-1/2 IF TOOL JOINT |

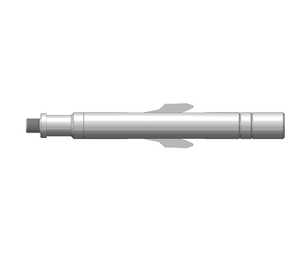

CEMENT RETAINER

The Cement Retainer is a drillable packer that provides the end user with a tool that will consistently contain well pressures at elevated temperatures and pressures. This tool is designed to be used for remedial cementing operations and light service applications. This tool permits faster removal from the well with either rotary or cable tool methods due to its compact size and the selection of high quality construction materials.

Special Features

Surface controlled valve

Allows pressure testing before squeeze

Valve automatically closes when the stinger is removed, locking in the squeeze pressure

Valve protects sensitive zones in low fluid wells

Simple conversion to bridge plug

Mechanical or wireline set available Components rotationally locked for easy drillout

Product Specifications

Casing | Recommended Hole Size (inches) | Tool OD (inches) | |

Size (inches) | Weight (lbs/ft) | ||

4-1/2 | 9.5 - 15.1 | 3.826 - 4.090 | 3.612 |

5 | 11.5 - 18.0 | 4.276 - 4.560 | 3.937 |

5-1/2 | 14.0 - 23.0 | 4.670 - 5.012 | 4.315 |

6-5/8 | 17.0 - 32.0 | 5.675 - 6.135 | 5.375 |

7 | 17.0 - 35.0 | 6.004 - 6.538 | 5.680 |

7-5/8 | 20.0 - 39.0 | 6.625 - 7.125 | 6.313 |

8-5/8 | 24.0 - 52.0 | 7.435 - 8.097 | 7.125 |

9-5/8 | 29.3 - 58.4 | 8.435 - 9.063 | 8.125 |

10-3/4 | 32.75 - 60.7 | 9.660 - 10.192 | 9.437 |

11-3/4 | 38.0 - 60.0 | 10.772 - 11.150 | 10.437 |

13-3/8 | 48.0 - 72.0 | 12.347 - 12.715 | 12.000 |

CR BRIDGE PLUG

The CR Bridge Plug provides the end user with tools that will consistently contain well pressures at evated temperatures and pressures. This plug permits faster removal from the well with either rotary or cable tool methods due to its

compact size and the selection of high quality construction material.

The short, compact, interlocked construction assures the user that the CR Bridge Plug will provide faster, safer run-in, dependable set and pack-off and hold pressure that is safe for the casing weight and grade. The interlock construction and compact size requires minimal material removal during drill out. The outside diameter of these products has been held to a minimum to provide maximum tool-to- casing clearance for safe running and maximum fluid by-pass area during displacement procedures even in heavy mud systems.

A Wireline Adapter Kit (WLAK) and Hydraulic Setting Tool are used for setting CR Bridge Plugs.

NOTE: The CR Bridge Plug is designed to provide a temporary wellbore seal. For a permanent wellbore seal, cement must be set on top of the plug.

Special Features

Convertible to Cement Retainer

Sets on wireline or on tubing with mechanical setting tool

Product Specifications

Casing | Recommended Hole Size (inches) | Tool OD (inches) | |

Size (inches) | Weight (lbs/ft) | ||

4-1/2 | 9.5 - 15.1 | 3.826 - 4.090 | 3.612 |

5 | 11.5 - 18.0 | 4.276 - 4.560 | 3.937 |

5-1/2 | 14.0 - 23.0 | 4.670 - 5.012 | 4.315 |

6-5/8 | 17.0 - 32.0 | 5.675 - 6.135 | 5.375 |

7 | 17.0 - 35.0 | 6.004 - 6.538 | 5.680 |

7-5/8 | 20.0 - 39.0 | 6.625 - 7.125 | 6.313 |

8-5/8 | 24.0 - 52.0 | 7.435 - 8.097 | 7.125 |

9-5/8 | 29.3 - 58.4 | 8.435 - 9.063 | 8.125 |

10-3/4 | 32.75 - 60.7 | 9.660 - 10.192 | 9.437 |

11-3/4 | 38.0 - 60.0 | 10.772 - 11.150 | 10.437 |

13-3/8 | 48.0 - 72.0 | 12.347 - 12.715 | 12.000 |

CIW BRIDGE PLUG

The CIW Bridge Plug is designed to have excellent running characteristics and secure sets. This plug can be set on different types of Wireline Pressure Setting Tools as well as with Hydraulic Setting Tools. This plug is designed for rapid drill-out while maintaining sufficient strength during the set. It is designed for high differential pressures and temperatures up to 250°F with standard Nitrile element and O-ring. Different elastomers are available for higher temperatures.

The short, compact, interlocked construction assures the CIW Bridge Plug will provide faster, safer run-in, dependable set and pack-off, and hold pressure that is safe for the casing weight and grade. The interlock construction and compact size requires minimal material removal during drill out.

Special Features

Electric, wireline or hydraulic set

Drillable, cast iron construction

One piece break-apart slips

Rubber extrusion resisting backups on elements

Sets with common setting sleeves

Locking mechanism for ease in drilling multiple plugs

Product Specifications

Casing | Recommended Hole Size (inches) | Tool OD (inches) | |

Size (inches) | Weight (lbs/ft) | ||

3-1/2 | 7.7 - 10.2 | 2.922 - 3.068 | 2.750 |

4-1/2 | 9.5 - 15.1 | 3.826 - 4.090 | 3.613 |

5-1/2 | 13.0 - 23.0 | 4.670 - 5.044 | 4.315 |

7 | 17.0 - 35.0 | 6.004 - 6.538 | 5.680 |

7-5/8 | 20.0 - 39.0 | 6.625 - 7.125 | 6.312 |

8-5/8 | 24.0 - 52.0 | 7.435 - 8.097 | 7.125 |

9-5/8 | 29.3 - 61.1 | 8.375 - 9.063 | 8.125 |

10-3/4 | 32.75 - 60.7 | 9.660 - 10.192 | 9.437 |

11-3/4 | 38.0 - 60.0 | 10.772 - 11.150 | 10.437 |

13-3/8 | 48.0 - 72.0 | 12.347 - 12.715 | 12.000 |

16 | 65.0 - 128.0 | 14.438 - 15.250 | 14.125 |

WIRELINE ADAPTER KIT - FOR CEMENT RETAINER & CR BRIDGE PLUG

The Wireline Adapter Kit (WLAK) for Cement Retainers and CR Bridge Plugs is used to set Cement Retainers and CR Bridge Plugs on electric wireline or with a hydraulic setting assembly on tubing. The WLAK is designed to be used ona Baker E-4 wireline powder charge or hydraulic setting assembly or any setting assembly with the same configuration.

The WLAK automatically disconnects from the Bridge Plug during packer setting to be easily retrieved and prepared to run again.

Product Specifications

Size (inches) | Tool OD (inches) | Wireline Setting Tool Box Up |

4-1/2 | 3.500 | BAKER E-4, #10 |

5-1/2 | 4.000 | BAKER E-4, #20 |

7 | 5.688 | BAKER E-4, #20 |

9-5/8 | 8.125 | BAKER E-4, #20 |

WIRELINE ADAPTER KIT - FOR CIW BRIDGE PLUG

The Wireline Adapter Kit (WLAK) for CIW Bridge Plugs is used to set CIW Bridge Plugs

on electric wireline or with a hydraulic setting assembly on tubing. The WLAK is designed to be used on a Baker E-4 wireline powder charge or hydraulic setting assembly, but can be used with any setting assembly with the same configuration.

Product Specifications

Size (inches) | Tool OD (inches) | Wireline Setting Tool Box Up |

3-1/2 | 2.600 | BAKER E-4, #05 |

4-1/2 | 3.500 | BAKER E-4, #10 |

5-1/2 | 4.240 | BAKER E-4, #20 |

7 | 5.250 | BAKER E-4, #20 |

8-5/8 | 6.750 | BAKER E-4, #20 |

9-5/8 | 7.750 | BAKER E-4, #20 |

10-3/4 | 8.750 | BAKER E-4, #20 |

11-3/4 | 10.200 | BAKER E-4, #20 |

13-3/8 | 11.000 | BAKER E-4, #20 |

16 | 13.500 | BAKER E-4, #20 |

DLT Retrievable Packer

The DLT Retrievable Packer is a compression set packer with hydraulic hold down that is designed to provide an extra measure of dependability for rugged service. The hydraulic actuated upper hold-down provides more than the usual surface area to ensure that the packer will not move up the hole. It is ideally suited for high pressure, high temperature service work.

Some unique features of this packer include positive rotational locks on all internal connections, which allow for extreme values of torque (left-hand or right-hand) to be transmitted through the packer. Backup rings on all the o-rings provide for more reliable sealing at high temperature and pressure.

This packer also comes with extra-long top and bottom subs which allow for hydraulic tong make-up and break out.

Special Features

Hydraulic actuated upper hold down slips

Positive rotational locks on all internal connections

Backup rings on all o-rings provide for more reliable sealing at high temperatures and high pressures

Available with extra-long top and bottom subs allowing hydraulic tong make-up and break out

Product Specifications

Casing | Recommended Hole Size (inches) | Gage OD (inches) | Max OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weight (lbs/ft) | |||||

7 | 17.0 - 23.0 | 6.366 - 6.538 | 6.188 | 6.2001 | 2.69 | 3-1/2 IF TOOL JOINT |

26.0 - 32.0 | 6.094 - 6.276 | 5.954 | - | 2.69 | 3-1/2 IF TOOL JOINT | |

32.0 - 38.0 | 5.920 - 6.094 | 5.781 | - | 2.69 | 3-1/2 IF TOOL JOINT | |

38.0 - 46.4 | 5.626 - 5.920 | 5.525 | - | 2.69 | 3-1/2 IF TOOL JOINT | |

7-5/8 | 24.0 - 29.7 | 6.875 - 7.025 | 6.672 | - | 2.69 | 3-1/2 IF TOOL JOINT |

33.7 - 39.0 | 6.625 - 6.765 | 6.453 | - | 2.69 | 3-1/2 IF TOOL JOINT | |

9-5/8 | 32.3 - 43.5 | 8.755 - 9.001 | 8.584 | - | 3.75 | 4-1/2 IF TOOL JOINT |

43.5 - 53.5 | 8.535 - 8.755 | 8.365 | - | 3.75 | 4-1/2 IF TOOL JOINT | |

58.4 - 59.4 | 8.407 - 8.435 | 8.250 | - | 3.75 | 4-1/2 IF TOOL JOINT | |

10-3/4 | 51.0 - 55.5 | 9.760 - 9.850 | 9.500 | - | 3.75 | 4-1/2 IF TOOL JOINT |

60.7 - 65.7 | 9.560 - 9.660 | 9.375 | - | 3.75 | 4-1/2 IF TOOL JOINT | |

71.1 - 73.2 | 9.406 - 9.450 | 9.125 | - | 3.75 | 4-1/2 IF TOOL JOINT | |

11-3/4 | 42.0 - 54.0 | 10.880 - 11.084 | 10.625 | - | 3.75 | 4-1/2 IF TOOL JOINT |

60.0 - 71.0 | 10.586 - 10.772 | 10.406 | - | 3.75 | 4-1/2 IF TOOL JOINT | |

13-3/8 | 48.0 - 77.0 | 12.275 - 12.715 | 12.000 | - | 3.75 | 4-1/2 IF TOOL JOINT |

80.7 - 92.0 | 12.031 - 12.215 | 11.750 | - | 3.75 | 4-1/2 IF TOOL JOINT | |

14 | 82.5 - 92.68 | 12.700 - 12.876 | 12.500 | - | 3.75 | 4-1/2 IF TOOL JOINT |

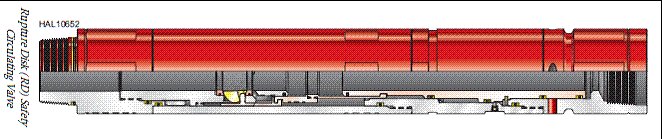

V-III UNLOADER

The V-III Unloader is designed as a high-pressure accessory for the DLT Retrievable Packer designed to withstand severe operating conditions. This unloader provides a means of equalizing tubing and annulus pressures as well as a by-pass to allow fluid to pass through the mandrel of the packer while running the tubing string in and out of the well. Circulating can be established to spot fluids to the packer or circulating debris from the hole.

Special Features

Standard slot locks in open and closed positions

Standard slot is right-hand close, right-hand open

Additional J-slot arrangements available

Product Specifications

Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down |

3-1/2 | 5.500 | 2.69 | 3-1/2 IF TOOL JOINT |

4-1/2 | 7.250 | 3.75 | 4-1/2 IF TOOL JOINT |

STORM VALVE

The Storm Valve is designed to run above a compression set packer similar to the DLT Retrievable Packer. The Storm Valve allows the drill pipe or tubing close to the surface to be disconnected without tripping the entire string. It is designed to be used in situations where the rig must be abandoned quickly. It can also be used for changing surface equipment without tripping a drill string. And it will remain closed to provide a secure seal until the drill pipe or tubing is re-connected.

Special Features

Rugged, field proven design

Pump-out plug allows full access for wireline and circulation

Automatic valve operation during disconnect and reconnect operations

Product Specifications

Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down |

4-3/4 | 5.469 | 1.50 | 3-1/2 IF TOOL JOINT |

6-1/8 | 6.125 | 2.00 | 4-1/2 IF TOOL JOINT |

BUMPER SUB

The Bumper Sub is a heavy duty travel joint that is designed to transmit high torque. A hex-shaped mandrel is incor- porated in the tool design providing a large contact surface which transmits the torque through the tool. Proven bonded seals are used to provide a seal across the full stroke of the bumper sub.

Special Features

Heavy duty design

Large contact surfaces to transmit high torque thru tool

Bonded seals provide seal on full stroke

Other extended lengths available

Product Specifications

Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down |

3-1/2 | 4.750 | 2.50 | 3-1/2 IF TOOL JOINT |

4-1/2 | 6.250 | 3.75 | 4-1/2 IF TOOL JOINT |

6.500 | 3.75 | 4-1/2 IF TOOL JOINT |

RR SAFETY JOINT

The RR Safety Joint is a means for backing off a workstring from tools below. Right-hand rotation and recip- rocation is needed to back off the release mechanism. Shear screws hold the mandrel locked until a straight pull shears the screws. This insures the back-off mechanism does not operate until needed.

Special Features

Shear release to eliminate premature back-off

Heavy duty construction

Product Specifications

Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down |

2-3/8 | 3.250 | 1.88 | 2-3/8 EUE |

2-7/8 | 4.500 | 2.50 | 2-7/8 EUE |

3-1/2 | 5.250 | 2.69 | 3-1/2 IF TOOL JOINT |

4-1/2 | 6.250 | 3.75 | 4-1/2 IF TOOL JOINT |

AXIAL INSTALLATION HD PACKER

The Axial Installation (AI) HD Packer is a heavy-duty service packer ideally suited for all types of squeeze cementing, formation fracturing, high pressure acidizing, etc. It is a large opening compression set packer with hydraulic button-type hold down. It is set and unset with simple up and down motion. This motion is controlled with a continuous J-slot so multiple settings are possible. This packer withstands high pressure from above or below and uses a 3-element packing system, J-slot, and a drag block mechanism for easy setting. The packer has a built-in unloader which circulates across the hold down buttons to improve retrievability and run in performance.

Special Features

Heavy duty design

No rotation at surface

Built-in unloader

Product Specifications

Casing | Recommended Hole Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weight (lbs/ft) | ||||

5-1/2 | 14.0 - 20.0 | 4.778 - 5.012 | 4.625 | 2.00 | 2-3/8 EUE |

20.0 - 23.0 | 4.670 - 4.778 | 4.500 | 2.00 | 2-3/8 EUE | |

6-5/8 | 24.0 - 32.0 | 5.675 - 5.921 | 5.500 | 2.50 | 2-7/8 EUE |

WR BRIDGE PLUG

The WR Bridge Plug is a wireline set, wireline retrieve, packer-type bridge plug capable of holding differential pressure from above or below. The WR Bridge Plug is used as a temporary bridge plug for acidizing, fracturing, cementing, casing pressure tests, wellhead replacement, and zone isolation. The WR Bridge Plug utilizes standard wireline or hydraulic setting tools.

Special Features

Wireline set/ wireline retrieve

10,000 psi differential pressure rating above and below the plug

Bi-directional slips

Equalization feature prevents premature release against differential pressure

Product Specifications

Casing | Recommended Hole Size (inches) | Tool OD (inches) | Top Connection | WLAK | Retrieving Tool | |

Size (inches) | Weight (lbs/ft) | |||||

3-1/2 | 7.7-10.2 | 2.922-3.068 | 2.700 | 5/8-18 UNF PIN | 73535-05 | 73535RT |

4 | 9.5-11.0 | 3.476-3.548 | 3.250 | 5/8-18 UNF PIN | 73535-05 | 73540RT |

10.46-12.95 | 3.340-3.476 | 3.187 | 5/8-18 UNF PIN | 73535-05 | 73540RT | |

4-1/2 | 9.5-13.5 | 3.920-4.090 | 3.750 | 1.000-8 UNC PIN | 73545-10 | 73545RT |

13.5-15.1 | 3.826-3.920 | 3.650 | 1.000-8 UNC PIN | 73545-10 | 73545RT | |

15.1-16.6 | 3.754-3.826 | 3.625 | 1.000-8 UNC PIN | 73545-10 | 73545RT | |

5 | 11.5-15.0 | 4.408-4.560 | 4.125 | 1.000-8 UNC PIN | 73545-10 | 73545RT |

18.0-21.0 | 4.154-4.276 | 3.969 | 1.000-8 UNC PIN | 73545-10 | 73545RT | |

5-1/2 | 13.0-20.0 | 4.778-5.156 | 4.625 | 7/8-14 UNF PIN | 73557-20 | 73557RT |

20.0-23.0 | 4.670-4.778 | 4.500 | 7/8-14 UNF PIN | 73557-20 | 73557RT | |

23.0-26.0 | 4.548-4.670 | 4.406 | 7/8-14 UNF PIN | 73554-20 | 73554RT | |

7 | 17.0-26.0 | 6.276-6.538 | 5.969 | 7/8-14 UNF PIN | 73570-20 | 73570RT |

26.0-32.0 | 6.094-6.276 | 5.875 | 7/8-14 UNF PIN | 73570-20 | 73570RT | |

COMPRESSION UNLOADER

The Compression Unloader is designed as a high-pressure accessory for compression set packers. The Unloader is run above the packer pinned in the open or closed position. After the packer is run to setting depth, the procedures required to set the packer will automatically close the unloader. With the packer set and the unloader closed, well operations may proceed.

When run above a compression set packer, the Compression Unloader is opened to allow differential pressure to equalize before releasing the packer below.

Special Features

The Compression Unloader can be pinned in the open or closed position

Allows equalizing of tubing/annulus pressure differential

When pinned in the open position, allows for fluid bypass through the ID of the packer to reduce swabbing of packer elements

Product Specifications

Casing | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down |

Size (inches) | |||

4-1/2 | 3.500 | 2.00 | 2-3/8 EUE |

7 | 5.500 | 2.867 | 3-1/2 EUE |

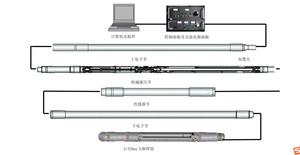

LATCH LOCATOR - FOR CEMENT RETAINER

The Latch Locator for Cement Retainer is designed to be run on tubing and is used to manipulate the Cement Retainer collet (a.k.a. sleeve valve) during cementing operations. The Latch Locator is designed with a latching mechanism to aid in maintaining connection between the Latch Locator and the Cement Retainer and to give a positive indication of release when removing the Latch Locator from the Cement Retainer.

Product Specifications

Size (inches) | Tool OD (inches) | Thread Connection Box Up |

4-1/2 | 3.48 | 2-3/8 EUE |

5-1/2 | 4.29 | 2-3/8 EUE |

7 | 5.648 | 2-7/8 EUE |

9-5/8 | 8.09 | 2-7/8 EUE |

13-3/8 | 11.737 | 2-7/8 EUE |

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559