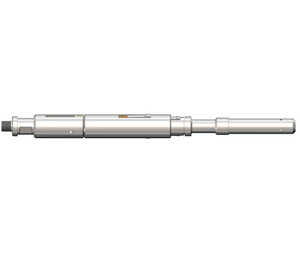

R3 double grip retrievable casing packer

Product Parameters

Product Parameters

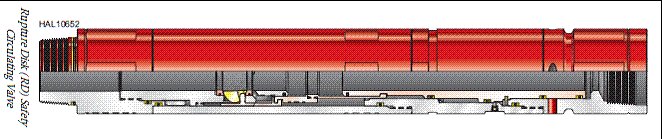

R-3 double grip retrievable casing packer Product family No. H64201R-3

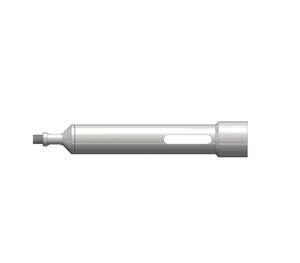

single grip retrievable casing packerProduct family No. H64101

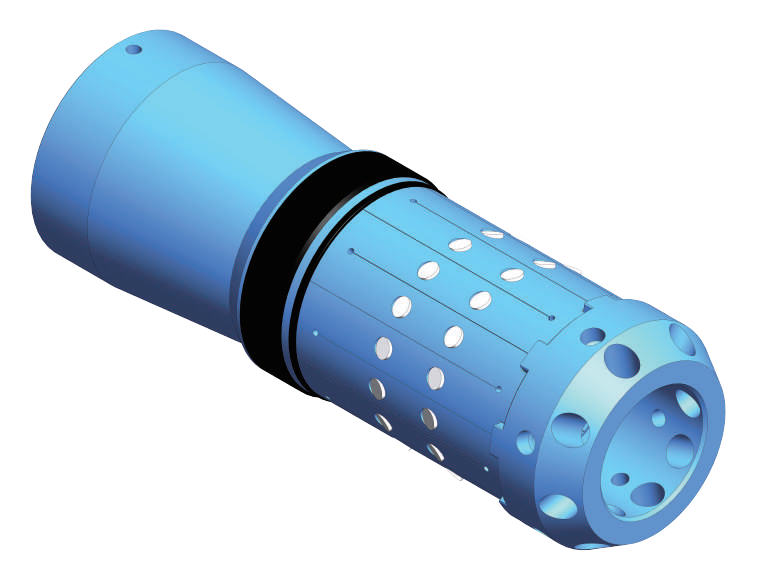

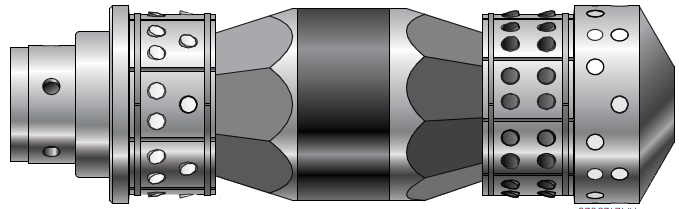

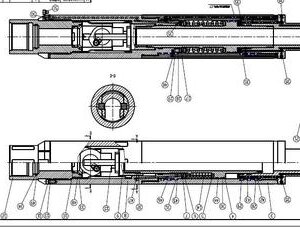

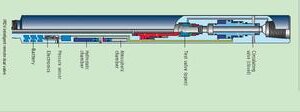

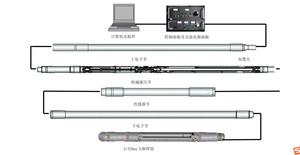

The R3™ packer is a versatile production packer intended for a broad range of production applications. It is a compressionset packer, suitable for stimulation and treating applications in a double-grip configuration. Applications in which excessive bottomhole pressures have been depleted, a single-grip version can be used as an economical production packer.Additional informationThe R-3 single-grip retrievable-casing packer is set with one-fourth-turn right-hand rotation and can be released with straight pickup

Advantages• Rugged rocker-type slips system • Hydraulic button-type hold-down located below bypass valve • Unique, built-in differential lock helps keep bypass closed • Effective bypass design allows rapid pressure equalization and resists swab off • Field-proven, three-piece packing element system

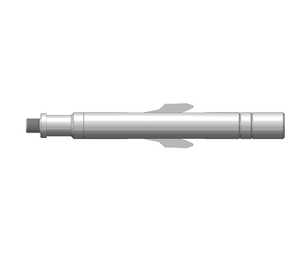

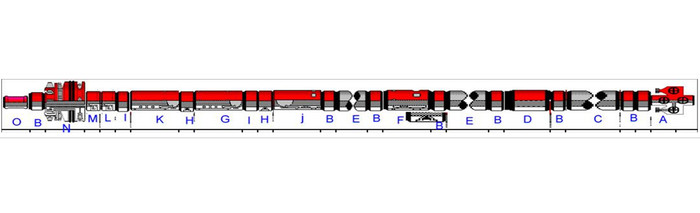

Model KW-3D Double Grip Retrievable Packer, R-3 TypeModel CR-3D Double Grip Retrievable Casing Packers are used in production, stimulation and testing applications. Their hydraulic hold down is below the pressure equalization valve. They feature a proven three element packing system and a balance sleeve device to assist in keeping the by-pass closed. They are available for 4½” through 9⅝” casing.Features: • Three piece packing element system• Hydraulic hold down button unit with large internal flow path located below the bypass valve to reduce element swabbing and button wicker dulling• Surface controlled combination bypass and equalizing valve• Tubing pressure actuated collet lock to eliminate excessive set down weight requirements• Parts are interchangeable with other manufacturers• Field-proven design“MR-3D” DOUBLE GRIP RETRIEVABLE PACKER••••••• Carbide slips available

SPECIFICATIONS | ||||||

Casing | Setting Range | Size | Tool OD (in.) | Threads Box Up Pin Down | ||

OD (in.) | Wt T & C (pounds) | Min ID (in.) | Max ID (in.) | |||

4½ | 9.5-13.5 | 3.910 | 4.090 | 43A | 3.771 | 2⅞ EU 8RD |

4½ | 9.5-13.5 | 3.910 | 4.090 | 43A | 3.771 | 2⅜ EU 8RD |

5 | 15.0-18.0 | 4.250 | 4.408 | 43B | 4.125 | |

5 5½ | 11.5-15.0 26.0 | 4.408 | 4.560 | 43C | 4.250 | |

5½ | 20.0-23.0 | 4.625 | 4.778 | 45A2 | 4.500 | |

5½ | 15.5-20.0 | 4.778 | 4.950 | 45A4 | 4.641 | |

5½ 5¾ 6 | 13.5-15.5 22.5 26.0 | 4.950 | 5.190 | 45B | 4.781 | |

5½ | 20.0-23.0 | 5.191 | 5.390 | 45C | 5.062 | |

5¾ | 15.0-18.0 | 5.391 | 5.560 | 45D | 5.156 | |

6 | 34.0 | 5.561 | 5.609 | 45E2 | 5.406 | |

6 | 28.0-32.0 | 5.610 | 5.791 | 45E4 | 5.484 | |

6 | 24.0-28.0 | 5.791 | 5.921 | 45EF | 5.484 | |

6⅝ | 28.0-32.0 | 5.600 | 5.791 | 46A2 | 5.475 | 2⅞ EU 8RD |

6⅝ 7 | 24.0-28.0 38.0 | 5.791 | 5.921 | 46A4 | 5.588 | |

6⅝ 7 | 17.0-20.0 32.0-35.0 | 5.922 | 6.135 | 46B | 5.781 | |

6⅝ 7 | 24.0 38.0 | 5.830 | 5.937 | 47A2 | 6.656 | |

6⅝ 7 | 17.0-20.0 32.0-35.0 | 5.938 | 6.135 | 47A4 | 5.812 | |

7 | 26.0-29.0 | 6.136 | 6.276 | 47B2 | 5.968 | |

7 | 26.0-29.0 | 6.136 | 6.276 | 47B2 | 5.968 | 3½ EU 8RD |

7 | 20.0-26.0 | 6.276 | 6.456 | 47B4 | 6.078 | 2⅞ EU 8RD |

7 | 17.0-20.0 | 6.454 | 6.578 | 47C2 | 6.266 | |

7⅝ | 33.7-39.0 | 6.579 | 6.797 | 47C4 | 6.453 | |

7⅝ | 24.0-29.7 | 6.798 | 7.025 | 47D2 | 6.672 | |

7⅝ | 20.0-24.0 | 7.025 | 7.125 | 47D4 | 6.812 | |

8⅝ | 44.0-49.0 | 7.511 | 7.687 | 49A2 | 7.312 | 3½ EU 8RD |

8⅝ | 32.0-40.0 | 7.688 | 7.921 | 49A4 | 7.531 | |

8⅝ | 20.0-28.0 | 8.017 | 8.191 | 49B | 7.781 | |

9⅝ | 47.0-53.5 | 8.343 | 8.681 | 51A2 | 8.218 | |

9⅝ | 40.0-47.0 | 8.681 | 8.835 | 51A4 | 8.437 | |

9⅝ | 29.3-36.0 | 8.836 | 9.063 | 51B | 8.593 | |

9⅝ | 40.0-47.0 | 8.681 | 8.835 | 51A4 | 8.437 | 2⅞ EU 8RD |

9⅝ | 29.3-36.0 | 8.921 | 9.063 | 51B | 8.593 | |

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559