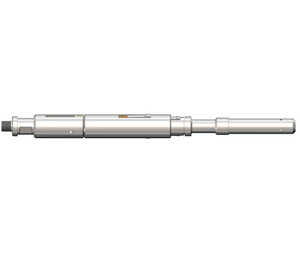

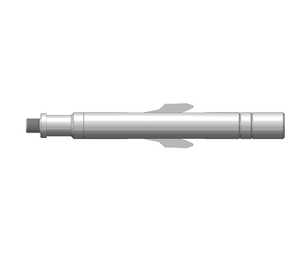

15K Super Safety Valve

Product Parameters

Product Parameters

15K Super Safety Valve

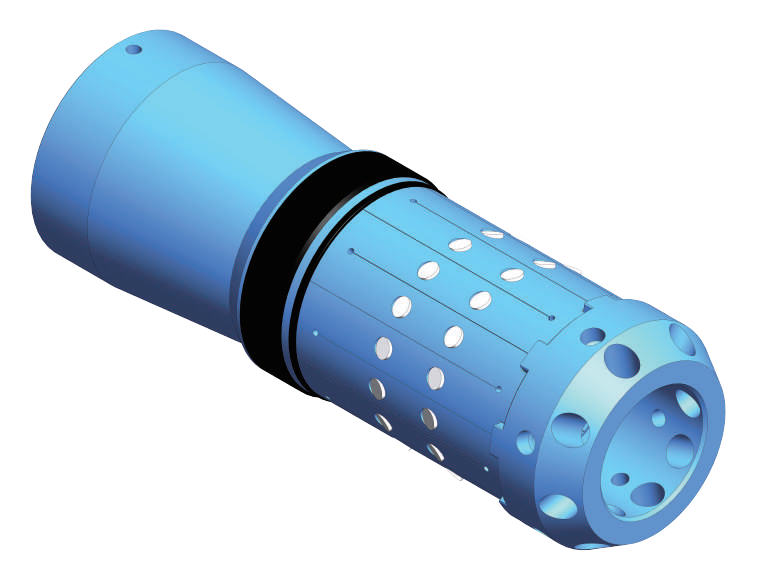

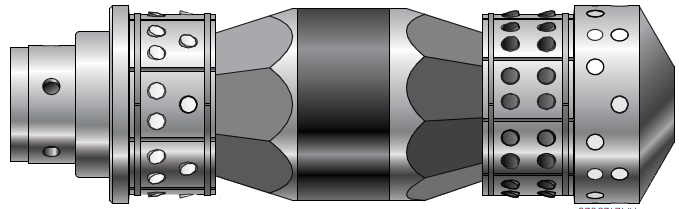

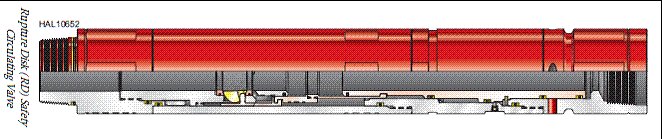

15K Super Safety Valve is a sort of downhole safety valve which is used with BOP for the drill stem testing operation to control the well flow. So during the downhole operation, the BOP safety valve is the fail safe safety valve.

Design Features of 15K Super Safety Valve

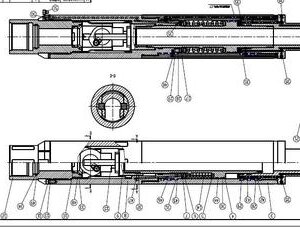

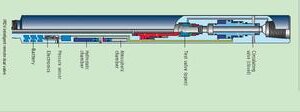

The BOP safety valve includes a new ball mechanism that has a 3.0 inch ID and the capability to cut coiled tubing as large as 1.50 inch OD x 0.125 inch wall thickness. During the design and testing of the 15K Super Safety Valve, a new high pressure plug assembly was qualified for 15000 psi. This plug seals with a metal-to-metal seal and an O-ring backup seal. In addition, a new high pressure connector was qualified for

15000 psi. This connector seals with a metal-to-metal seal, and is a direct connection to a hose using a 3/8" medium pressure female swivel.

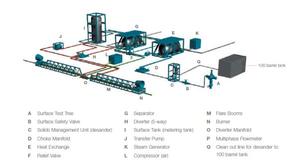

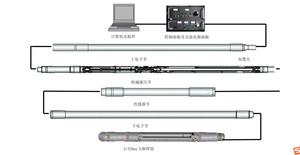

Remote control panel of the BOP safety valve

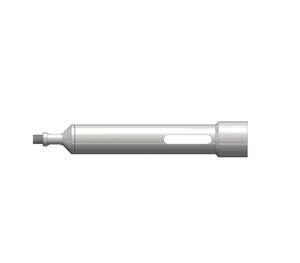

Generally, the balance line does not have pressure applied to it, therefore the floating check valve remains on seat. However, the balance line can be used for additional closing force if required. The nitrogen charge and spring force will cut mono conductor cable or coiled tubing and close the ball valve provided the nitrogen chamber was charged to the appropriate pressure

The control line is pressurized to hold the ball valve open. The pressure required can be determined, but generally two times the nitrogen dome charge pressure plus 500 psi for lower pressures and temperature

is sufficient. There is little hydrostatic pressure and no requirement for cutting coiled tubing in most normal operations.

The chemical injection line is rated for 15000 psi and can be used for chemical injection downhole or to control a subsurface safety valve. The chemical injection line is an independent line that is not affected by the ball valve being open or closed.

Technical Parameter of Super Safety valve

| No | Specification | 8" |

| 1 | O.D. | 203.2mm |

| 2 | Bore Diameter | 76.5mm |

| 3 | Make Up Length | 2855.5mm |

| 4 | Working pressure | 105Mpa |

| 5 | Tensile strength | 6299KN |

| 6 | Torque strength | 137.6KN.m |

| 7 | Service condiction | H2S,NACE MR0175, Full H2S |

| 8 | Working temperature | -29oC+204oC |

| 9 | Material of the SSV body | AISI 4140 or Inonnel 718 |

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559