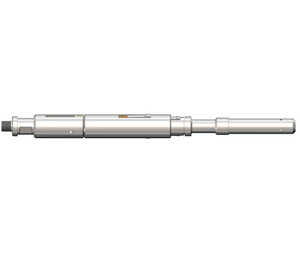

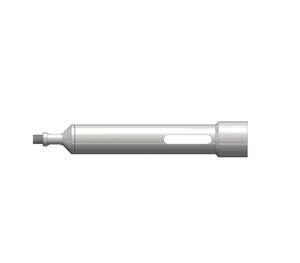

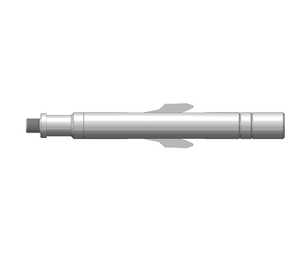

Damping tools

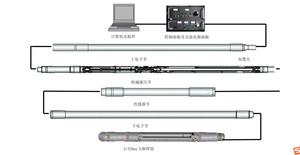

Product Parameters

Product Parameters

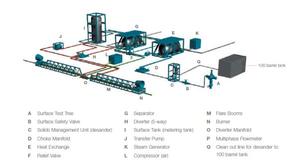

Abstract:

Anti-Vibration tool is a future bright star in metal industry which bring an effective solution to the long overhang cutting tool chatter problem, especially in the deep hole processing applications widely But there has been monopolized by foreign brands knives and domestic knives manufacturing has always been difficult to hold a candle. Sunder- tools has committed to build the first national brand of boring tool, and damping boring tool will be developed to be a insurmountable gap. Study Sunder-tools R & D team unswerving commitment damping system, and finally overcome this problem!

In the development of process, to fully investigate the dynamic vibration damping technology and technology, combined with expertise and experience in research and design has developed a unique damping system EC and its structure, the tool helps. precisely to minimize the vibration amplitude fast; also studied cutting flutter control technology to facilitate accurate determination of different areas.

The type of vibration, for For general tools effectively control these vibrations in an aspect ratio of more than four times the tool itself will produce vibrations, so that can not be processed. With a growing overhang longer, the tool will become increasingly rigid low cutting forces will affect the amplitude of vibration of the cutting tool will be growing.

In the cutting tool, the vibration can not be completely eliminated, but the damping boring tool can be reduced to the lowest level so that the results of the process and does not cause adverse Impact. Using advanced simulation methods, measuring equipment and systems, by optimizing the structure of the tool parameters and various parts in the normal cutting zone, boring tool vibration damping. The system can eliminate the adverse effects of vibration on the tool cutting forces generated by the cutting process.

All in all, Sunder-tools damping tool can help you achieve a lower cost of individual parts.

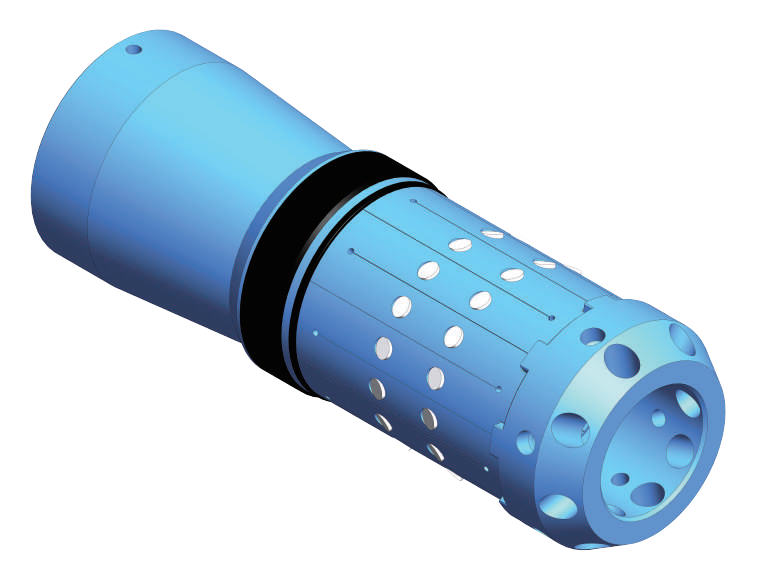

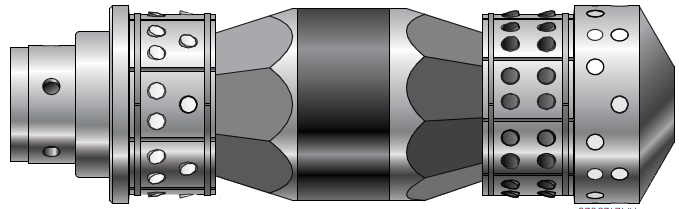

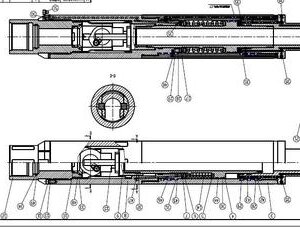

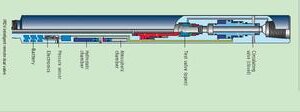

Principle:

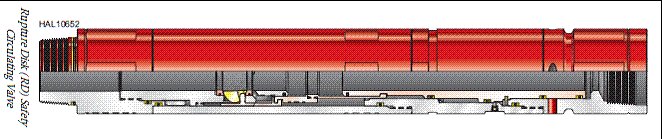

Internal damping tool has a good pre-tuned damping system, which consists of a plurality of rubber spring elements supported by the heavy metal media components. Fill oil increase the damping effect.

For the long tool overhangs and between the flanges, and recommended that the spindle shank two sided touch.

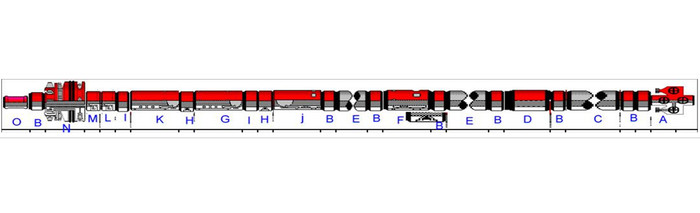

Choose the right tool

Its essential to choosing the right tool for the best productivity and processing results . For each length / diameter ratio of processing applications always provide the best solution, the damping system is still a good performance in specific conditions.

Each tool has a specific damping overhang range, to achieve the best performance tool to ensure that each use of the tool in the correct range is important

Scope of work specification:

When the tool overhang is more than three times the diameter of the tool and use the tool vibration can improve production efficiency.

For tool overhang is 4 times the tool diameter applications, use vibration tools cutting parameters can generally be increased by at least 50%; the tool overhang is 6 times tool diameter above applications and to achieve excellent productivity and excellent hole quality and surface quality, vibration tool is the only option. If the standard products do not meet your application for length, diameter, interfaces, and other specifications of requirements, our custom tool also has the best performance.

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559