Downhole Tool_Downhole Motor_downhole motor drilling mud motor

Product Parameters

Product Parameters

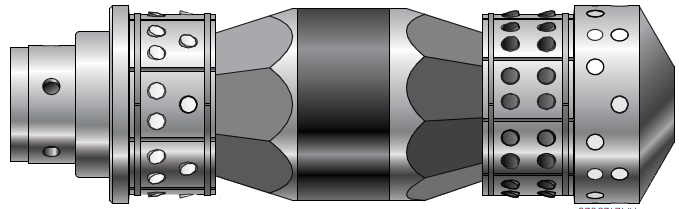

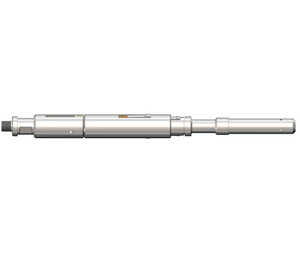

KINGWELL Downhole Drilling Motor is a powerful and reliable positive displacement motor. Using the latest available technology and materials, it can be configured to answer specific downhole conditions or well designs.

KINGWELL Downhole Drilling Motor is a powerful and reliable positive displacement motor. Using the latest available technology and materials, it can be configured to answer specific downhole conditions or well designs.

The motor generates an optimum balance of rotational speed and high torque to drive a variety of drill bits at speeds that maximize tool life and performance.

KINGWELL MOTORS are used in applications such as straight hole drilling, directional (steerable) drilling, horizontal drilling, hole opening, and re-entry(work over).

KINGWELL integrates new technology into enhancing the performance of downhole motors foroilfield exploration and production. Using the latest available technology and materials, it can beconfigured to answer specific downhole conditions or well designs. The motor generates anoptimum balance of rotational speed and high torque to drive a variety of drill bits at speeds thatmaximize tool life and performance.Application1. Directional Drilling2. Horizontal Drilling3. Performance Drilling4. Workover5. HDD6. Geo-thermalBy offering multiple configurations, KINGWELL motors can accommodate almost any type of drillingand drilling conditions. Each motor is assembled to meet our customer`s specifications to ensuremaximum performance.

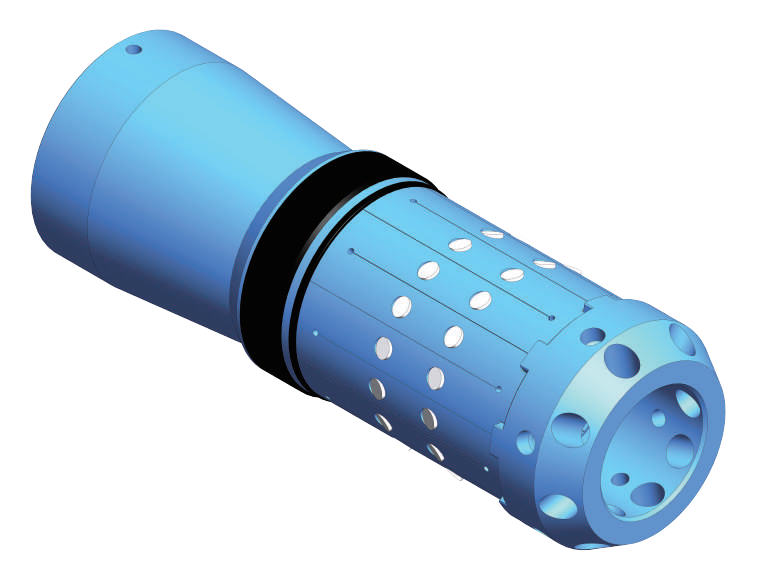

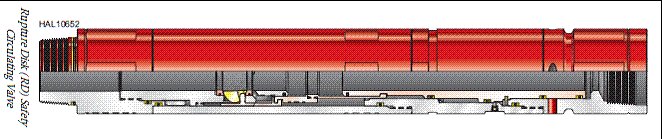

Technology Advantages:1. Adjustable Bend HousingNew design on universal coupling is applied to downhole motor withadjustable bend housing achieving 19 points for adjust ranging from 0 degreeto 4 degree, avoiding the disadvantages of shorter running life, easiercorrosion on bare surface of flat universal coupling, accordingly extendingthe running

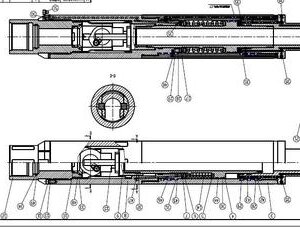

. Heat-resistant Power SectionElastomer in the stator of anti-resistant power section made by specialtechnics guarantees well-balanced running of stator under 180 ℃. As aresult, the stator can be employed in to high temp drilling well and deepdrilling well.

. Anti-drop Device on RotorAnti-dropping of rotor can be achieved by employing anti-drop device indownhole motor if rupture and thread taken off happens on the housing.Meanwhile, rise of the pressure loss of pump makes operator on earthdiscover the problems timely to avoid the accident

Anti-break Device on Drive ShaftCarring capability of the drive shaft is achieved by improving material,meliorating technics, perfecting structure design and eliminating stress point,which makes downhole motor suitable for drilling in super deep well such asdirectional well with large pitch or horizontal well and for oriented rotarydrilling

5. Bearing Section Assembly in New Transmission SealNew design of transmission seal applied to bearing section assemblyincreasing the size of contact area effectively between transmission parts,decreasing the contact stress between the parts, decreasing the contactstress between the parts is helpful to improve the carring capability andextend the running life of universal coupling.

. Uniform Thickness Power SectionIt will extend running life of downhole motor and improve running efficiencyof the motor. The characteristics are: Good cooling speciality improves the running life of the stator. Working stability is risen by uniform thickness of the rubber System efficiency is rised up by high pressure bear on single stage. Conglutinant size is increased by rising up the contact between rubberand the metal.

Non-magnetic Downhole MotorThe material for Cross-over sub, stator and rotor is non-magnetic material.So the non-magnetic drilling collar is not necessary for such motor, whichreduces the distance from measuring point to bit and improves theaccuracy of the motor.This technics solves the interruption problem on measuring instrument dueto the magnetism from complete downhole motor, achieving accuratemeasuring result.

. Oil Seal Drive ShaftPressure loss in the drive shaft can be coordinated by the change of outer pressure, which makesthe pressure loss between inside and outside be in balance to prolong the running life of the sealingdevice.

9. Technology on Surface of RotorSpecial chroming coating technics by KINGWELL will control the ratebetween peak and valley of the coating attaching to 1:1. Tungsten Carbidecoating rotor successfully solves the corrosion problem of chroming rotorin saturated salt water based mud, which successfully solves thecorrosion problem of chroming rotor in saturated salt water based mud

Material Management of Core PartsSpecial upgrade on technics of universal coupling and on forgingof drive shaft will secure the durable capacity of the spare partsprolonging the running life of the complete downhole motor.

. Technology on Low/Medium/High Speed Power SectionPower section in various lobes, stages and lead distance can be designed according to drillingparametersHigh Speed/Low Torque Power SectionPower section in this type is suitable to PDC bit, soft formation anddirectional drilling operation.Medium Speed/Medium Torque Power SectionMotor with lobe 5:6 is commonly used in generally directional and horizontaldrilling well. For example, motor in 5:6 lobe can be used by matching withPDC bit and tricone bit for drilling rock

Low Speed/High Torque Power SectionMotor with lobe 7:8 is commonly used in medium hard formation fordirectional drilling and horizontal drilling matching with PDC bit or triconebit.

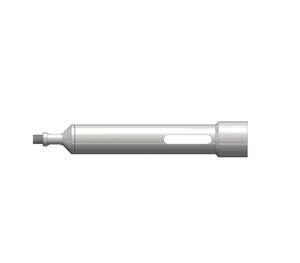

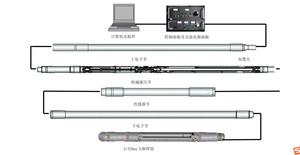

KINGWELL Stator Bore Gauge

Stator Admeasuring Apparatus of KINGWELL is specially used to

measure ID of the stator, supplying the basic guarantee for ID

measuring of the stator. KINGWELL admeasuring apparatus with

characteristics in higher technics, more accuracy compared to other

testing tools is available to supply accurate measure data to stator,

securing the perfect fit between stator and the rotor.

13. KINGWELL Hydraulic Breakout Unit

Hydraulic breakout unit used for motor assemble and disassemble is

one automatic device with six claws clipping and bilateral sliding

achieving clamping , sliding, spinning and drawing in series, which

reduced the labor strength and improves the working efficiency.

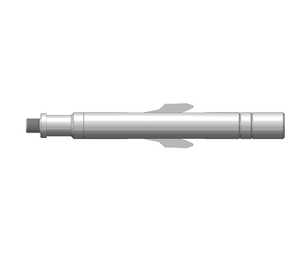

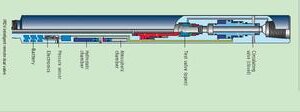

14. KINGWELL Downhole Motor Tester

Power section tester is used in measuring the fit between rotor and stator

of downhole motor, elevating the reasonable degree of streamline on

power section and showing the testing parameters. KINGWELL downhole

motor tester realizes the parameters test on output torque, transporting

torque, pressure loss test between outlet and inlet and the parameter test

on the flowrate

Many CAE technology are applied to the project, such as contact analysis, hydraudynamicsanalysis, static finite element analysis etc..

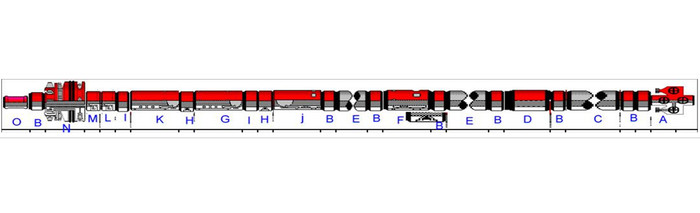

| Flow Rate | Pressure Drop | Rating Torque | Max.Torque | Bit Weight | Power | OD | Length | Connections | ||

Box up | box down | ||||||||||

5LZ43×7.0 | 0.5~1.5 | 108 | 173 | 6 | 3.68 | 43(11/16) | 3.3 | M27*2 | |||

5LZ60×7.0 | 1.26~3.13 | 2.5 | 160 | 280 | 5 | 2.35~6.03 | 60(23/8) | 3.3 | 1.9TBG | ||

5LZ73×7.0 | 1.26~5.05 | 3.5 | 275 | 480 | 12 | 3.5~13.82 | 73(27/8) | 3.45 | 23/8 TBG | 23/8 REG | |

5LZ89×7.0 | 2~7 | 4.1 | 560 | 980 | 18 | 5.6~19.35 | 89(31/2) | 4.67 | 23/8 REG | ||

5LZ95×7.0 | 4.73~11.04 | 3.2 | 950 | 1240 | 21 | 10.4~23.79 | 95(33/4) | 3.7 | 27/8 REG | ||

C5LZ95×7.0 | 5~13.33 | 6.5 | 1490 | 2384 | 55 | 21.8~59.3 | 95(33/4) | 6.88 | 27/8 REG | ||

5LZ100×7.0 | 4.73~11 | 3.2 | 710 | 1240 | 21 | 10.4~23.79 | 100(37/8) | 4.35 | 27/8 REG | ||

5LZ120×7.0 | 5.78~15.8 | 2.5 | 1300 | 2275 | 55 | 9.5~27.23 | 120(43/4) | 4.88 | 31/2 REG | ||

C5LZ120×7.0 | 6.667~20 | 5.2 | 2500 | 4000 | 55 | 70.5 | 120(43/4) | 6.88 | 31/2 REG | ||

D5LZ120×7.0 | 5.78~15.8 | 1.6 | 900 | 1440 | 55 | 6.6~18.85 | 120(43/4) | 3.29 | 31/2 REG | ||

3LZ165×7.0 | 17~27 | 4.1 | 2500 | 3750 | 80 | 78.54 | 165(61/2) | 6.5 | 41/2 REG | ||

5LZ165×7.0 | 16~28(47) | 3.2 | 3200 | 5600 | 80 | 33.5~59.65 | 165(61/2) | 6.25 | 41/2 REG | ||

D7LZ165×7.0 | 18~28 | 2.5 | 2300 | 3680 | 80 | 30.4~47.2 | 165(61/2) | 4.7 | 41/2 REG | ||

9LZ165×7.0 | 19~31.6 | 2.5 | 3200 | 5600 | 100 | 45.24 | 165(61/2) | 5.7 | 41/2 REG | ||

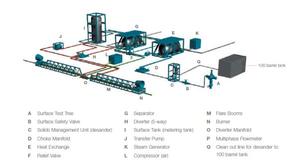

kingwell Drilling Motors specializes in the design, manufacturing, and support of downhole drilling motors. Bosun offers high quality downhole mud motors ranging from 2-7/8” to 9-5/8” outer diameter for drilling various hole sizes. Bosun motors have a history of over ten years and have been used extensively in both domestic and international drilling applications. Bosun strives to provide the best in quality, performance, and value.Motor Serviceskingwell Drilling Motors offers complete downhole tools services including tool assembly/disassembly, cleaning, inspection, repair, and maintenance. kingwell is also a complete source for motor spare parts and components. This includes rotors, stators, couplings, radial bearings, bearing assemblies, and stabilizers. Bosun has a staff of highly experienced personnel to provide technical support with issues concerning all aspects of drilling motor design, function, operations, and troubleshooting.The kingwell Hydraulic Breakout Unit (shown below) is designed specificallyfor servicing downhole motors. For more information about the Unit or available motor services, please contact us directly.

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559