Retrievable Whipstock

Product Parameters

Product Parameters

Introduction

Retrievable whipstock is the key tools in branch well drilling technologies. It plays a vital role for branch well drilling and completion.

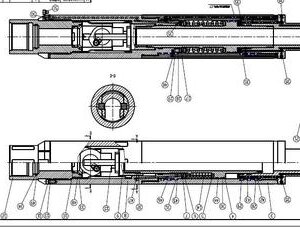

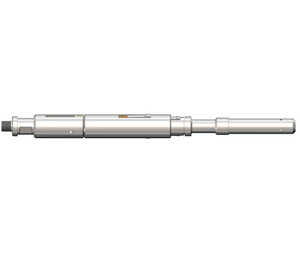

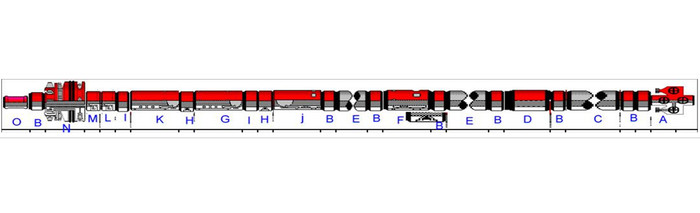

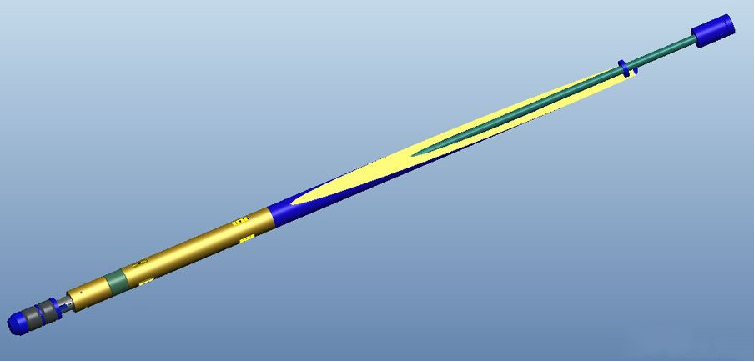

It is divided into three parts including whipstock, circulation flushing valve and recovery tool.

1. Whipstock

Whipstock adopts hydraulic pressure sealing which is firm and easy to operate. The inclined plane is arc-like and receives super hardening treatment. The milling cone coincides highly with the inclined plane when window cutting. Due to easy controlled drilling pressure, the can drill and dance drill phenomenon is decreasing. Tool internal self-locking mechanism is more perfect. It adopts axial and circumferential self-locking methods which greatly improve the tool reliability.

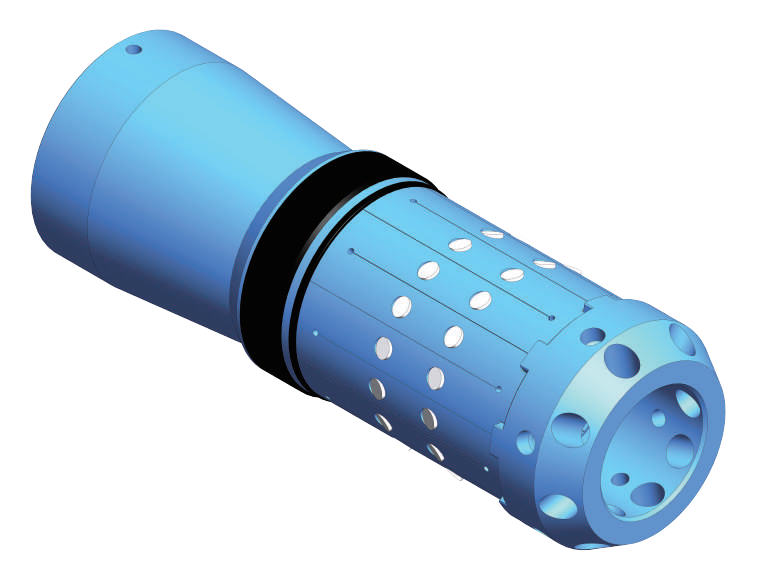

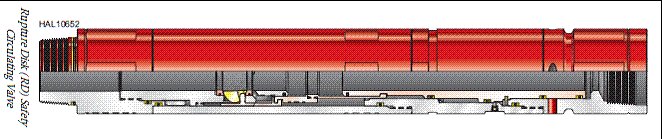

2. Circulation Flushing Valve

Flushing valve is mainly performed fluid communication when tools are descending, reverse circulation flushing and normal circulation pressure sealing effect. Interior designed special guide mechanism improves tool reliability because it ensures that flushing liquid is smoothly connected when tools are descending, at the same time, avoids the pipe column solid phase particles and impurities to precipitate into the whipstock interior.

3. Recovery tool

Recovery tool adopts double salvage agencies, every component part is independent and interrelated. Therefore, it greatly improves the return rate of recovery tools.

Applied Pipe | Whipstock | Circulation Flushing Valve | Recovery tool | Adapted Deviation | Adapted Temperature | Sealing Type | ||||||

Outline Dimensions | Buckle type | Bevel Angle | Bevel Length | Arc-like Diameter | Outline Dimensions | Buckle type | Outline Dimensions | Clipping Pressure | ≤90° | ≤200℃ | Direct Pressure Sealing | |

5 1/2" (φ139.7) | φ116x3464 | 210 | 3.2° | 1900 | φ125 | φ116x540 | 211x230 | φ116x3856 | 40KN | |||

7" (φ177.8) | φ150x3960 | 310 | 3.2° | 2515 | φ165 | φ150x630 | 311x330 | φ150x4460 | 60KN | |||

9 5/8" (φ244.4) | φ210x4850 | 410 | 4° | 2650 | φ225 | φ210x710 | 411x430 | φ210x4960 | 80KN | |||

Integral Construction Hydraulic Pressure Whipstock

Introduction

The exploitation of many oil fields has reached the mid-final stage. The old wells recovery and the accident wells increased gradually. The technology of window cutting sidetracking,as a main method to solve these problems, has received wide application.

The conventional whipstock fenestration needs two operations, whip stock and fenestration, which are complex and expensive. However, integral type whip stock realizes the two operations at a time, so it shortens the construction period and save the cost.

The integral construction hydraulic pressure whipstock made by our company has lots of advantages, such as easy operating, firm sealing and short window cutting time and so on.

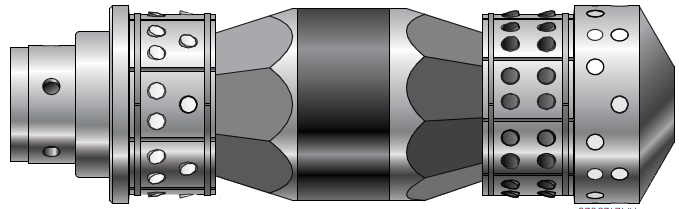

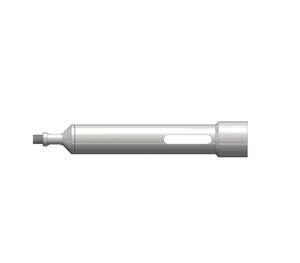

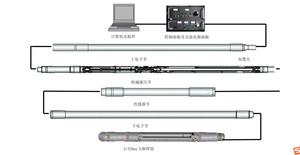

The integral construction hydraulic pressure whipstock is divided into two parts including whipstock and window cutting milling cone.

1. Whipstock

Whipstock adopts hydraulic pressure sealing which is firm and easy to operate. The inclined plane is arc-like and receives super hardening treatment. The milling cone coincides highly with the inclined plane when window cutting. Due to easy controlled drilling pressure, the can drill and dance drill phenomenon is decreasing. Tool internal adapts safe and reliable pressure transmitting mechanism. The more perfect self-locking mechanism adopts axial and circumferential methods which greatly improve the tool reliability.

2. Window Cutting Milling Cone

Window cutting milling cone and whipstock cooperate to complete window cutting work in pipe. Considering designing, tool shape, cutting edge angle and alloy block selection are optimized. The window cutting milling cone assembles window cutting and fixing as integrality. This design improves the construction speed and shortens the period.

ntroduction

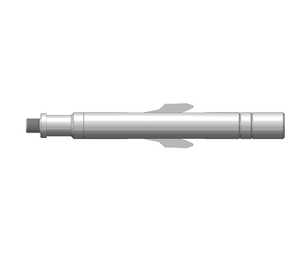

Window Milling Taper is equipped with the deflector to complete window cutting in the casing.

The window milling taper is integrated with window cutting and window repair, which can complete window cutting and repair operations once to improve construction speed, thus meeting site construction requirements properly.

In terms of design, tool appearance, alloy cutting edge angle and selection all are subject to optimization design.

Window Milling

ntroduction

Window Milling Taper is equipped with the deflector to complete window cutting in the casing.

The window milling taper is integrated with window cutting and window repair, which can complete window cutting and repair operations once to improve construction speed, thus meeting site construction requirements properly.

In terms of design, tool appearance, alloy cutting edge angle and selection all are subject to optimization design.

Deflector

Introdution

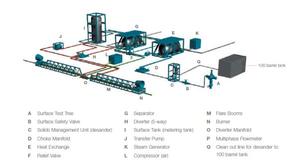

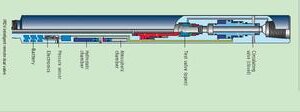

Deflecting tools produced by our company include ground anchor type deflector and hydraulic setting slip type deflector.

Hydraulic setting slip type deflector is provided with accurate direction, solid setting and other characteristics. When reservoir casing is seriously damaged or reservoir collapsed and buried by sands so that oil wells cannot produce oils, in order to use the upper casings and reduce costs of drilling ahead, window sidetracking can be made on the upper casing on the top of the reservoir to form new boreholes for oil production.

Window sidetracking in the casing is an important means to drill a deviated well in a well with the lower casings seriously damaged so as to make the well restore production capacity.

Window sidetracking tools mainly include deflector and window milling taper.

Product Specification and Code | Applicable Casing | Structural Form | Overall Dimension (mm) | Bevel Angle | Bevel Length (mm) | Window Length (mm) | Applicable Well Deviation | Applicable Well Temperature | Setting Method | Connection Thread |

DEF102 | 5 "(ф127) | Common type | ф102x3210 | 3℃ | 1730 | 1600- 1800 | ≤40° | ≤200° | Hydraulic setting by ball injecting ★or direct hydraulic setting | 2⅞REG |

DEF102F | Leak protection type | ф102x3720 | ||||||||

DEF114 | 5 1/2" (ф139.7) | Common type | ф114x 3450 | 1900 | 1800- 2000 | NC31★or 2⅞REG | ||||

DEF114F | Leak protection type | ф114x3960 | ||||||||

DEF142 | 6 5/8"(ф168.28) | Common type | ф142x3940 | 2415 | 2000- 2200 | NC38★or 3½REG | ||||

DEF142F | Leak protection type | ф142x4450 | ||||||||

DEF150 | 7"(ф177.8) | Common type | ф150x4000 | 2515 | 2400- 2500 | NC38★or 3½REG | ||||

DEF150F | Leak protection type | ф150x4200 | ||||||||

DEF160 | 9 5/8" (ф193.68) | Common type | ф160x4200 | 2700 | 2500- 2700 | NC38★or 3½REG | ||||

DEF160F | Leak protection type | ф160x4400 | ||||||||

DEF210 | 9 5/8"(ф193.68) | Common type | ф210×4600 | 4℃ | 2600 | 2700-3000 | NC50★or 4½REG | |||

DEF210F | Leak protection type | ф210×4800 | ||||||||

DEF300 | 13 3/8"(ф339.7) | Common type | ф300×5600 | 4030 | 3800-4300 | NC50★or 4½REG | ||||

DEF300F | Leak protection type | ф300×5800 |

1.Window Mill

The WINDOW MILL is designed to mill the window as fast and safe as possible. The design of the Mill will grind the casing like a fine metal powder instead of metal shavings of chips. With the round nose and radial ground design of the WINDOW MILL, it is virtually impossible to mill up the Eaton BOTTOMTRIP WHIPSTOCK.

2.Watermelon Mills

The WATERMELON MILL is made to run in tandem with other Window Mill is designed in such a way that it can mill up or down. The WATERMELON MILL is also designed to grind up casing into a fine metal powder instead of metal shavings.

3.Starting mill

The STARTING MILL is a specialized Milling tools used for orientation of the BOTTOMTRIP WHIPSTOCK as well as landing and setting of the BOTTOMTRIP WHIPSTOCK in a predetermined direction. After shearing the setting stus, the milling operation begins, guided by a tapered pilot, creating the initial cutting of the casting window.

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559