Full Hydraulic Drilling Jar

Product Parameters

Product Parameters

Model “FHD super jar” Full Hydraulic Drilling Jar is a kind of unfreezing tool when they get stuck. It is an integral hydraulic jar with up jarring and down jarring. It adopts the valve structure, making time-lag more stable and performance more reliable. The time-lag of Model “FHD super jar” Full Hydraulic Drilling Jar can generate the elastic elongation of drill string richly, reserving energy as to obtain the best jarring effect. When downhole tools are stuck, “FHD super jar” Full Hydraulic Jar can offer a huge impact force to unfreeze. As a result, common drilling operation can be regained rapidly.

When the “FHD super jar” jar is used, operators can adjust to pick it up or slack it off on surface to create up jarring impact or down jarring impact (without adjustment to the outside part) and can adjust impact freely within permissible range. The “FHD super jar” jar can be operated easily and conveniently with high reliability and applied to downhole operations, such as drilling, coring, fishing, workover, etc.

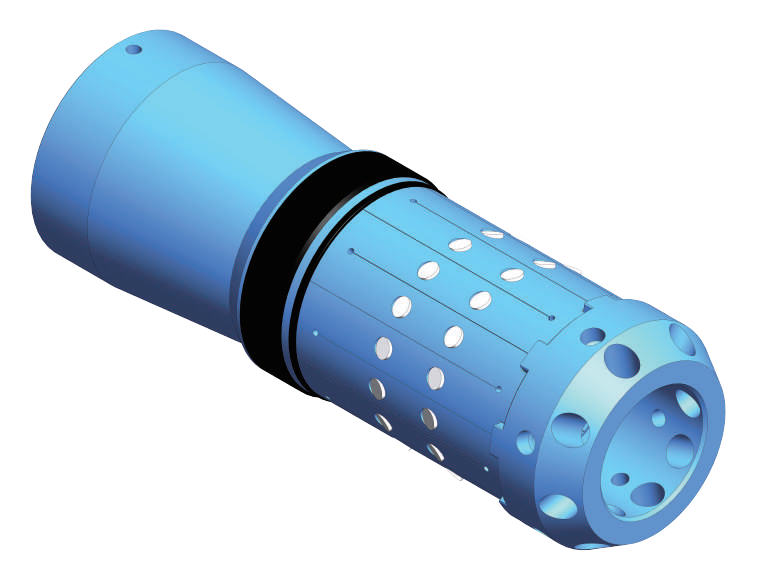

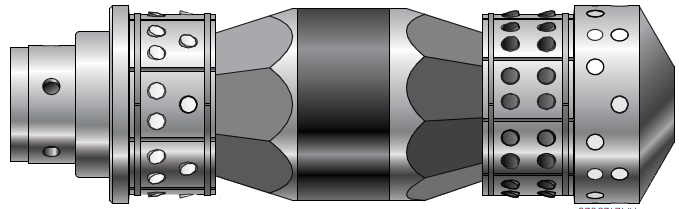

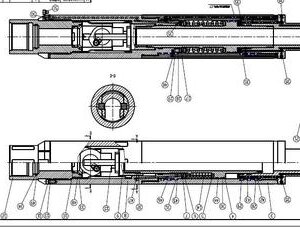

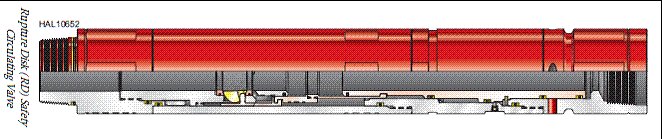

1. STRUCTURE

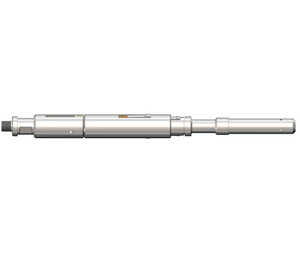

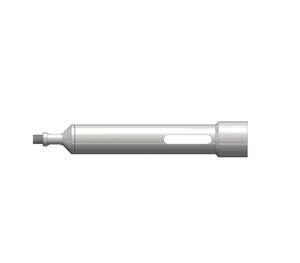

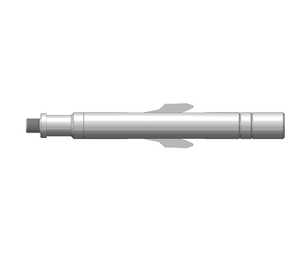

The basic structure of Model “FHD super jar” Full Hydraulic Drilling Jar is shown in right figure.

Model “FHD super jar” Full Hydraulic Drilling Jar mainly consists of Mandrel, Spline Housing, Upper Jar Pad, Top Mandrel, Cylinder, Lower Jar Pad, Connector, Balancing Piston, Middle Mandrel, Valve, Filter Core, Plug, Lower Mandrel, Pressure Body, Down Sub and Seals, etc.

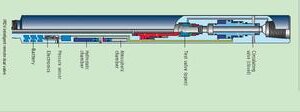

2. WORKING PRINCIPLE

3.1 Principle of Up Jarring: The up jarring is realized through picking up the drill string to create up jarring load. Mandrel drive top valve to move in upper hydraulic cylinder, chamber becomes small with top valve movement gradually. The hydraulic oil in the hydraulic chamber is pressed to produce suppression pressure, that is, make drill string store energy. When up jarring reaches a certain stroke, suppression pressure oil suddenly offloads, thus the stored energy in drill string is released and then the up jarring impact is generated.

3.2 Principle of Down Jarring: Similar to the principle of up jarring, the storing energy is realized through the downward motion of down valve in lower hydraulic cylinder, slacking off the drill string to apply load on mandrel. After the stored energy gets a certain extent, the down jarring impact can be generated momentarily.

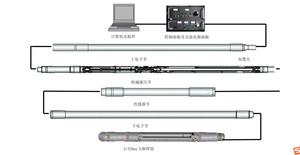

3. USAGE AND OPERATION

4.1 Usage

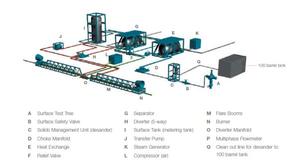

1) Before down to hole, the Jar should be taken surface test. After test, only the qualified jar can be used.

2) Check if all oil- plugs are tightened-up or not.

3) On the rotary table, first connect the jar with drilling tools and then remove collar clamp. The jar should be lowered into hole together with drilling tools.

4) The jar with drill collar or heavy drill pipe can be assembled to be a stand, but the jar should be connected at the top of the stand.

5) The jar is be fittingly connected and placed at upper section of neutralization point of integral drilling tool assembly to make the jar in tension.

6) The O.D. of the jar should be less than or equal to the diameter of drill collar and lower drilling tool.

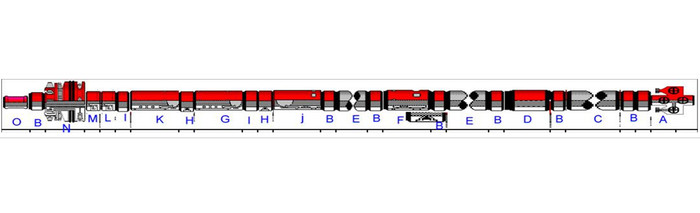

7) Recommended drilling tool assembly:

Upper drill tools+ Heavy drill pipe (Its O.D. should be less than or equal to O.D. of the jar) + Full hydraulic drilling jar type QY III + Drill collar (Its O.D. should be larger than or equal to O.D. of the jar) + Lower drill strings

4.2 Operation

4.2.1 Up Jarring Operations:

1)Slack down the drill tools. If weight indicator reading exceeds tool weight above Jar by 5 -7 tons, it can make the “Up-jarring damping mechanism” return.

2)Pick up tool, then wait the jar to do impact operation. The Up-jarring Load: Final upward Weight Indicator Reading before impact subtracts suspending weight Above the Jar.

3)To repeat above steps for realize continuously up jarring.

4.2.2 Down Jarring Operations:

1)Lower tool, then wait the jar to do impact operation. The Down-jarring Load: Final downward Weight Indicator Reading before impact subtracts suspending weight Above the Jar.

2)Pick up the drill tools. If weight indicator reading exceeds tool weight above Jar by 5 -7 tons, it can make the inner Jar mechanism return.

3)Immediately slack off drill tool ,then wait jar to impact.

4)To repeat above steps for realize continuously down jarring.

Note:

It’s limited that lifting or dropping loads on jar can be larger than the working load designed to withstand. (See Table -1). Jar must be on extended position while being handled, so the safety clamp must be on the wellhead and be removed above the rotary table.

4. SPECIFICATIONS AND PERFORMANCE

Specification Series and Performance Parameter see Table 1.

Table 1. Specification Series and Performance Parameter

Model | QY121Ⅲ | QY127Ⅲ | QY165Ⅲ | QY178Ⅲ | QY203Ⅲ |

O.D. of Too mm(in) | 121 (4 3/4) | 127 (5) | 165 (6 1/2) | 178 (7) | 203 (8) |

I.D. of Too mm(in) | 50 (2) | 50 (2) | 57 (2 1/4) | 70 (2 3/4) | 76.2 (3) |

Connection API | NC38 | NC38 | NC50 | NC50 | 6 5/8REG |

Permissible work pull kN(Ib) | 1100 (250000) | 1100 (250000) | 2000 (450000) | 2400 (540000) | 2800 (630000) |

Permissibl working torque kN.m(Ib·ft) | 15 (11000) | 15 (11000) | 25 (18000) | 30 (22000) | 35 (26000) |

Max. Up Jarring kN (Ib) | 350 (78000) | 350 (78000) | 700 (160000) | 800 (180000) | 1000 (225000) |

Max. Down Jarring kN (Ib) | 180 (40000) | 180 (40000) | 350 (78000) | 400 (90000) | 500 (110000) |

UP Stroke Mm(in) | 152 | 152 | 152 | 152 | 152 |

Down Stroke mm(in) | 152 | 152 | 152 | 152 | 152 |

Pull Length mm(in) | 5768 | 5768 | 5939 | 6000 | 6000 |

NOTE: The seal pressure for waterhole is 30MPa, For 73-146 OD,the service temperature is 150℃, For 159-241 OD, the service temperature is 120℃。 | |||||

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559