Mechanical Set Packers

Product Parameters

Product Parameters

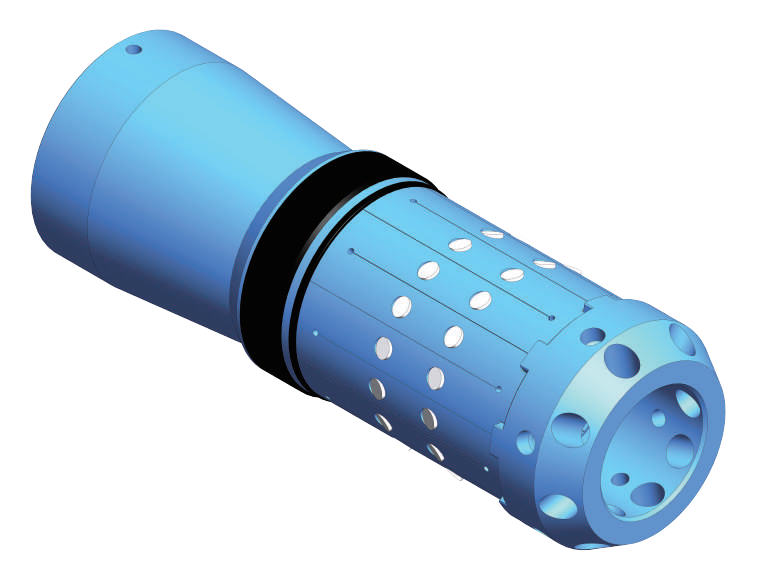

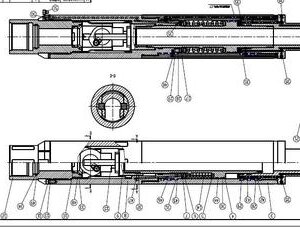

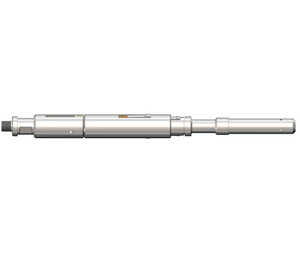

ASI-X PACKER

The ASI-X Single String Double-Grip Production Packer is the most versatile of the mechanically set retrievable packers and may be used in any production application. This packer is suited for treating, testing, or injection applications, in pumping or flowing wells, either deep or shallow. This packer can be left in tension or compression depending on well conditions and the required application.

A large internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set and opens prior to releasing the upper slips when retrieving to allow pressure equalization. The J-slot design allows easy setting and releasing; 1/4 turn right-hand set, 1/4 turn right-hand release.

The standard ASI-X Packer is designed for differential pressures up to 7,000 PSI (unless noted otherwise). This packer is also available in an HT version which is designed for differential pressures up to 10,000 PSI (unless noted otherwise). The HT version allows this packer to be utilized in completions where high pressure treating operations are performed and it is desirable to leave the tool in the well for production.

Special Features

By-pass below upper slips to wash debris when valve is opened

By-pass is opened before upper slips are released

Can be set with tension for shallow well applications

Can be left in tension, compression or neutral

1/4 turn right-hand set, 1/4 turn right-hand release

Additional J-Slot arrangements available

Product Specifications

Casing | Recommend Hole Size (inches) | GageOD(inches) | Max OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down | |||||

Size (inches) | Weight (lbs/ft) | |||||||||

2-7/8 | 6.4 - 6.5 | 2.375 - 2.441 | 2.250 | 2.2631 | 0.63 | 1.050 EUE | ||||

8.6 | 2.259 | 2.125 | 2.1521 | 0.63 | 1.050 EUE | |||||

3-1/2 | 7.5 - 7.7 | 3.068 - 3.250 | 2.938 | - | 1.25 | 1.900 NUE | ||||

7.7 - 10.2 | 2.922 - 3.068 | 2.781 | - | 1.25 | 1.900 NUE | |||||

12.95 | 2.750 | 2.562 | - | 1.00 | 1.315 EUE / 1.660 EUE | |||||

4 | 9.5 - 11.0 | 3.476 - 3.548 | 3.250 | 3.3121 | 1.50 | 1.900 EUE | ||||

10.46 - 12.95 | 3.340 - 3.476 | 3.187 | - | 1.50 | 1.900 EUE | |||||

4-1/2 | 9.5 - 13.5 | 3.920 - 4.090 | 3.750 | - | 1.94 | 2-3/8 EUE | ||||

13.5 - 15.1 | 3.826 - 3.920 | 3.650 | - | 1.94 | 2-3/8 EUE | |||||

15.1 | 3.826 | 3.641 | - | 1.94 | 2-3/8 EUE | |||||

15.1 - 16.6 | 3.754 - 3.826 | 3.594 | - | 1.50 | 1.900 EUE | |||||

18.8 | 3.640 | 3.437 | - | 1.50 | 1.900 EUE | |||||

5 | 11.5 - 15.0 | 4.408 - 4.560 | 4.125 | 4.2201 | 1.94 | 2-3/8 EUE | ||||

15.0 - 18.0 | 4.276 - 4.408 | 4.063 | - | 1.94 | 2-3/8 EUE | |||||

18.0 - 20.8 | 4.156 - 4.276 | 4.000 | 4.0101 | 1.94 | 2-3/8 EUE | |||||

21.4 | 4.126 | 3.938 | - | 1.94 | 2-3/8 EUE | |||||

5-1/2 | 13.0 - 14.0 | 5.012 | 4.813 | - | 2.38 | 2-7/8 EUE | ||||

14.0 - 20.0 | 4.778 - 5.012 | 4.625 | - | 2.00 | 2-3/8 EUE | |||||

- | 2.38 | 2-7/8 EUE | ||||||||

20.0 - 23.0 | 4.670 - 4.778 | 4.500 | - | 2.00 | 2-3/8 EUE | |||||

- | 2.38 | 2-7/8 EUE | ||||||||

23.0 - 26.0 | 4.548 - 4.670 | 4.375 | - | 1.94 | 2-3/8 EUE | |||||

4.406 | - | 2.38 | 2-7/8 EUE | |||||||

5-3/4 | 15.0 - 16.1 | 5.201-5.240 | 5.000 | - | 2.00 | 2-3/8 EUE | ||||

- | 2.38 | 2-7/8 EUE | ||||||||

17.6 - 19.4 | 5.083-5.146 | 4.875 | - | 2.00 | 2-3/8 EUE | |||||

- | 2.38 | 2-7/8 EUE | ||||||||

21.5 - 24.0 | 4.909-5.004 | 4.720 | - | 2.00 | 2-3/8 EUE | |||||

- | 2.38 | 2-7/8 EUE | ||||||||

6 | 10.0 | 5.672 | 5.375 | - | 2.50 | 2-7/8 EUE | ||||

12.0 - 20.0 | 5.352 - 5.620 | 5.188 | - | 2.38 | 2-7/8 EUE | |||||

6-5/8 | 17.0 - 24.0 | 5.921 - 6.135 | 5.750 | - | 2.50 | 2-7/8 EUE | ||||

20.0 - 24.0 | 5.921 - 6.049 | 5.750 | - | 3.00 | 3-1/2 EUE | |||||

24.0 - 32.0 | 5.675 - 5.921 | 5.500 | - | 2.50 | 2-7/8 EUE | |||||

- | 3.00 | 3-1/2 EUE | ||||||||

32.0 - 34.5 | 5.575 - 5.675 | 5.312 | - | 2.50 | 2-7/8 EUE | |||||

7 | 17.0 - 20.0 | 6.456 - 6.538 | 6.250 | 6.2811 | 2.50 | 2-7/8 EUE | ||||

- | 3.00 | 3-1/2 EUE | ||||||||

17.0 - 26.0 | 6.276 - 6.538 | 6.000 | 6.0621 | 2.50 | 2-7/8 EUE | |||||

6.1251 | 3.00 | 3-1/2 EUE | ||||||||

26.0 - 32.0 | 6.094 - 6.276 | 5.875 | - | 2.50 | 2-7/8 EUE | |||||

5.9361 | 3.00 | 3-1/2 EUE | ||||||||

29.0 - 35.0 | 6.004 - 6.184 | 5.812 | - | 2.50 | 2-7/8 EUE | |||||

35.0 | 6.004 | 5.812 | - | 3.00 | 3-1/2 EUE | |||||

7-5/8 | 24.0 - 29.7 | 6.875 - 7.025 | 6.672 | - | 2.50 | 2-7/8 EUE | ||||

- | 3.00 | 3-1/2 EUE | ||||||||

33.7 - 39.0 | 6.625 - 6.765 | 6.453 | - | 2.50 | 2-7/8 EUE | |||||

- | 3.00 | 3-1/2 EUE | ||||||||

8-5/8 | 20.0 - 24.0 | 8.097 - 8.191 | 7.750 | - | 2.50 | 2-7/8 EUE | ||||

20.0 - 28.0 | 8.017 - 8.191 | 7.750 | 7.8271 | 4.00 | 4-1/2 EUE | |||||

24.0 - 40.0 | 7.725 - 8.097 | 7.500 | - | 2.50 | 2-7/8 EUE | |||||

- | 3.00 | 3-1/2 EUE | ||||||||

32.0 - 40.0 | 7.725 - 7.921 | 7.500 | - | 4.00 | 4-1/2 EUE | |||||

44.0 - 49.0 | 7.511 - 7.625 | 7.312 | - | 2.50 | 2-7/8 EUE | |||||

9-5/8 | 32.3 - 43.5 | 8.755 - 9.001 | 8.500 | - | 4.00 | 4-1/2 EUE | ||||

43.5 - 53.5 | 8.535 - 8.755 | 8.250 | - | 4.00 | 4-1/2 EUE | |||||

10-3/4 | 32.75 - 51.0 | 9.850 - 10.192 | 9.625 | - | 4.00 | 4-1/2 EUE | ||||

51.0 - 65.7 | 9.560 - 9.850 | 9.312 | - | 4.00 | 4-1/2 EUE | |||||

11-3/4 | 42.0 - 65.0 | 10.682 - 11.084 | 10.438 | 10.5021 | 4.00 | 4-1/2 EUE | ||||

66.7 - 80.5 | 10.406 - 10.656 | 10.200 | - | 4.00 | 4-1/2 EUE | |||||

13-3/8 | 54.5 - 77.0 | 12.275 - 12.615 | 12.000 | - | 4.00 | 4-1/2 EUE | ||||

16 | 65.0 - 109.0 | 14.688 - 15.250 | 14.438 | - | 5.00 | 7” LTC | ||||

18-5/8 | 87.5 - 117.5 | 17.439 - 17.755 | 17.000 | - | 5.00 | 7” LTC | ||||

20 | 133.0 - 169.0 | 18.376 - 18.730 | 18.000 | - | 5.00 | 7” LTC | ||||

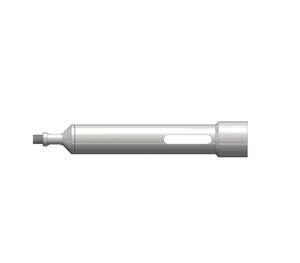

WIRELINE ADAPTER KIT - FOR VSI-X PACKER

The Wireline Adapter Kit (WLAK) for VSI-X Packers and VSI X HT Packers is used with a stinger to set VSI-X Packers and VSI-X HT Packers on electric wireline or with a hydraulic setting assembly on tubing. The WLAK is designed to be used on a Baker E-4 wireline powder charge, hydraulic setting assembly or any setting assembly with the same configuration.

When used with a Profile Stinger, the plug-in place design allows the running of a profile blanking plug to be run in place to convert the packer to a temporary Bridge Plug. Use of a profile blanking plug also reduces debris build-up and eliminates the need to run Profile Nipples or Pump-Out Plugs below the packer.

The WLAK automatically disconnects from the packer during packer setting to be easily retrieved and prepared to run again.

Product Specifications

Casing Size (inches) | Description |

2-7/8 | For 2-7/8” VSI-XW Packer |

3-1/2 | For #5 Hydraulic Setting Tool |

For 3-1/2” VSI-XW Packer (12.95#) | |

4 | For 4” VSI-XW Packer |

4-1/2 | For 4-1/2” VSI-XW Packer |

For 4-1/2” VSI-XW Packer (13.5-15.1#) Short Version | |

For 4-1/2” VSI-XW Packer (15.1#) | |

5-1/2 | For 5-1/2” X 2-3/8” VSI-XW Packer* |

For 5-1/2” X 2-7/8” VSI-XW Packer (23.0 - 26.0#) | |

For 5-1/2” X 2-7/8” VSI-XW Packer (23.0 - 26.0#) * | |

For 5-1/2”, 6-5/8”, 7”, 7-5/8” X 2-7/8” VSI-XW Packer | |

For: 5-1/2”, 7”, 7-5/8” X 2-7/8” VSI-XW Packer Short Version* | |

7 | For 7” X 3-1/2” VSI-XW Packer |

9-5/8 | For 8-5/8” & 9-5/8” X 2-7/8” VSI-XW Packer |

For 9-5/8” X 3-1/2” VSI-XW Packer | |

For 8-5/8” & 9-5/8” X 4-1/2” VSI-XW Packer | |

10-3/4 | For 8-5/8” Through 10-3/4” X 4-1/2” VSI-XW Packer |

VSI-X PACKER

The VSI-X Single String Double-Grip Production Packer is one of the most versatile packers on the market. This packer is a modification of the ASI-X Packer with the advantage of being able to set on electric line or hydraulically.

An On Off Tool Stinger with a Wireline Plug installed can be attached to the top of this packer. This packer can then be lubricated in the hole and set under pressure. Once set, casing pressure can be bled off, and the tubing with an On-Off Tool Overshot can be run and latched onto the packer. The Wireline Plug can then be removed.

This packer easily converts to a mechanically set ASI-X Packer – just remove the shear screws and install drag blocks and drag block springs. The ASI-X Packer sets with 1/4 right-hand rotation and releases with 1/4 right-hand rotation. The ASI-X Packer can be left in tension, compression or neutral.

NOTE: Stinger and setting equipment must be purchased separately.

Special Features

Wireline or tubing set

Sequentially released upper slip system

By-pass valve opens before upper slips are released

Available in shear release

Easily converts to ASI-X version - 1/4 turn to set, 1/4 turn to release

Product Specifications

Casing | Recommended Hole Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weight (lbs/ft) | ||||

2-7/8 | 6.4 - 6.5 | 2.375 - 2.441 | 2.250 | 0.63 | 1.050 EUE |

3-1/2 | 7.5 - 7.7 | 3.068 - 3.250 | 2.938 | 1.25 | 1.900 NUE |

7.7 - 10.2 | 2.922 - 3.068 | 2.781 | 1.25 | 1.900 NUE | |

12.95 | 2.750 | 2.562 | 1.00 | 1.315 EUE / 1.660 EUE | |

4 | 9.5 - 11.0 | 3.476 - 3.548 | 3.250 | 1.50 | 1.900 EUE |

10.46 - 12.95 | 3.340 - 3.476 | 3.187 | 1.50 | 1.900 EUE | |

4-1/2 | 9.5 - 13.5 | 3.920 - 4.090 | 3.750 | 1.94 | 2-3/8 EUE |

13.5 - 15.1 | 3.826 - 3.920 | 3.650 | 1.94 | 2-3/8 EUE | |

15.1 | 3.826 | 3.641 | 1.94 | 2-3/8 EUE | |

15.1 - 16.6 | 3.754 - 3.826 | 3.594 | 1.50 | 1.900 EUE | |

18.8 | 3.640 | 3.437 | 1.50 | 1.900 EUE | |

5 | 11.5 - 15.0 | 4.408 - 4.560 | 4.125 | 1.94 | 2-3/8 EUE |

18.0 - 20.8 | 4.156 - 4.276 | 4.000 | 1.94 | 2-3/8 EUE | |

21.4 | 4.126 | 3.938 | 1.94 | 2-3/8 EUE | |

5-1/2 | 13.0 - 14.0 | 5.012 - 5.044 | 4.813 | 2.38 | 2-7/8 EUE |

14.0 - 20.0 | 4.778 - 5.012 | 4.625 | 2.00 | 2-3/8 EUE | |

2.38 | 2-7/8 EUE | ||||

20.0 - 23.0 | 4.670 - 4.778 | 4.500 | 2.00 | 2-3/8 EUE | |

2.38 | 2-7/8 EUE | ||||

23.0 - 26.0 | 4.548 - 4.670 | 4.390 | 1.94 | 2-3/8 EUE | |

4.406 | 2.38 | 2-7/8 EUE | |||

6 | 12.0 - 20.0 | 5.352 - 5.620 | 5.188 | 2.38 | 2-7/8 EUE |

6-5/8 | 17.0 - 24.0 | 5.921 - 6.135 | 5.750 | 2.50 | 2-7/8 EUE |

20.0 - 24.0 | 5.921 - 6.049 | 5.750 | 3.00 | 3-1/2 EUE | |

24.0 - 32.0 | 5.675 - 5.921 | 5.500 | 2.50 | 2-7/8 EUE | |

3.00 | 3-1/2 EUE | ||||

32.0 - 34.5 | 5.575 - 5.675 | 5.312 | 2.50 | 2-7/8 EUE | |

7 | 17.0 - 26.0 | 6.276 - 6.538 | 6.000 | 2.50 | 2-7/8 EUE |

3.00 | 3-1/2 EUE | ||||

26.0 - 32.0 | 6.094 - 6.276 | 5.875 | 2.50 | 2-7/8 EUE | |

3.00 | 3-1/2 EUE | ||||

29.0 - 35.0 | 6.004 - 6.184 | 5.812 | 2.50 | 2-7/8 EUE | |

7-5/8 | 24.0 - 29.7 | 6.875 - 7.025 | 6.672 | 2.50 | 2-7/8 EUE |

3.00 | 3-1/2 EUE | ||||

33.7 - 39.0 | 6.625 - 6.765 | 6.453 | 2.50 | 2-7/8 EUE | |

3.00 | 3-1/2 EUE | ||||

8-5/8 | 20.0 - 28.0 | 8.017 - 8.191 | 7.750 | 4.00 | 4-1/2 EUE |

24.0 - 40.0 | 7.725 - 8.097 | 7.500 | 2.50 | 2-7/8 EUE | |

3.00 | 3-1/2 EUE | ||||

32.0 - 40.0 | 7.725 - 7.921 | 7.500 | 4.00 | 4-1/2 EUE | |

44.0 - 49.0 | 7.511 - 7.625 | 7.312 | 2.50 | 2-7/8 EUE | |

9-5/8 | 32.3 - 43.5 | 8.755 - 9.001 | 8.500 | 4.00 | 4-1/2 EUE |

43.5 - 53.5 | 8.535 - 8.755 | 8.250 | 4.00 | 4-1/2 EUE | |

10-3/4 | 32.75 - 51.0 | 9.850 - 10.192 | 9.625 | 4.00 | 4-1/2 EUE |

51.0 - 65.7 | 9.560 - 9.850 | 9.312 | 4.00 | 4-1/2 EUE | |

11-3/4 | 42.0 - 65.0 | 10.682 - 11.084 | 10.438 | 4.00 | 4-1/2 EUE |

13-3/8 | 54.5 - 77.0 | 12.275 - 12.615 | 12.000 | 4.00 | 4-1/2 EUE |

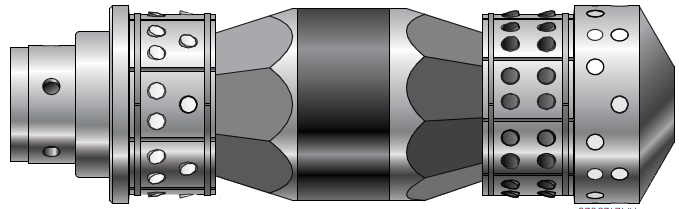

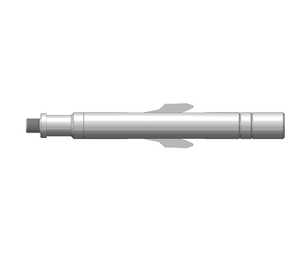

JETTSET PACKER

The Jettset Packer is a versatile mechanically set retrievable packer and may be used in any production application. This packer is suited for treating, testing, or injection applications, in pumping or flowing wells, either deep or shallow. This packer can be left in tension or compression, depending on well conditions and the required application. An internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set and opens prior to releasing the upper slips when retrieving to allow pressure equalization. The J-Slot design allows easy setting and releasing; 1/4 turn right-hand set, 1/4 turn right-hand release.

This packer is rated to 7,000 PSI and can be configured with different elastomers and metallics to suit downhole conditions.

Special Features

By-pass below upper slips to wash debris whenvalve is opened

By-pass is opened before upper slips are released

Can be set with tension for shallow well applications

Can be left in tension, compression or neutral

1/4 turn right-hand set, 1/4 turn right-hand release standard

Additional J-Slot arrangements available

Short, compact design

Product Specifications

Casing | Recommended Hole Size (inches) | Gage OD (inches) | Max OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weight (lbs/ft) | |||||

4-1/2 | 9.5 - 13.5 | 3.920 - 4.090 | 3.750 | - | 1.94 | 2-3/8 EUE |

7 | 17.0 - 26.0 | 6.276 - 6.538 | 6.000 | 6.0621 | 2.50 | 2-7/8 EUE |

AS-II PACKER

The AS-II Packer is a large-opening, compression-set packer with mechanical slip hold-downs. This packer withstands high pressure from above or below by using a 3-element packing system, and upper and lower mechanical slips. A J-slot and a drag block mechanism are incorporated for easy setting. This packer has a built-in unloader which circulates across the mechanical hold-down slips to improve retrievability. The unloader has a pressure compensating piston to keep it closed when pressure is greater below the set packer.

The AS-II Packer is available in the standard J-slot arrangement - right-hand auto set with straight pick-up release. Other J-slot arrangements are available: right-hand manual set, left-hand auto set, and left-hand manual set. All J-slot arrangements are straight pick-up release.

Special Features

Large internal by-pass

Mechanical slips vs. hydraulic buttons

Differential pressure holds valve closed

Additional J-slot arrangements available

Product Specifications

Casing | Recommended Hole Size (inches) | Gage OD (inches) | Max OD (inches) | Min ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weight (lbs/ft) | |||||

2-7/8 | 6.4 - 6.5 | 2.375 - 2.441 | 2.250 | 2.2631 | 0.62 | 1.050 EUE |

3-1/2 | 7.7 - 10.2 | 2.922 - 3.068 | 2.781 | - | 1.25 | 1.900 NUE |

2.938 | - | 1.25 | 1.900 NUE | |||

4 | 9.5 - 11.0 | 3.476 - 3.548 | 3.250 | 3.3121 | 1.50 | 1.900 EUE |

4-1/2 | 9.5 - 13.5 | 3.920 - 4.090 | 3.750 | - | 1.94 | 2-3/8 EUE |

15.1 | 3.826 | 3.656 | - | 1.94 | 2-3/8 EUE | |

5 | 11.5 - 18.0 | 4.276 - 4.560 | 4.125 | 4.2201 | 1.94 | 2-3/8 EUE |

18.0 - 21.4 | 4.126 - 4.276 | 4.000 | - | 1.94 | 2-3/8 EUE | |

5-1/2 | 14.0 - 17.0 | 4.892 - 5.012 | 4.625 | - | 2.00 | 2-3/8 EUE |

14.0 - 20.0 | 4.778 - 5.012 | 4.625 | - | 2.38 | 2-7/8 EUE | |

20.0 - 23.0 | 4.670 - 4.778 | 4.500 | - | 2.00 | 2-3/8 EUE | |

- | 2.38 | 2-7/8 EUE | ||||

AS-III PACKER

The AS-III Packer is a single-grip packer with no upper hold-down for use where no differential pressure from below is present. From the packing elements down, this packer operates identically to the AS-II Packer. This packer also features a large by-pass area to prevent swabbing when running or retrieving. This packer is ideal for isolating casing holes or perforations when used as the lower packer in conjunction with the Snapset Packer as the upper packer.

Special Features

Large internal by-pass

1/4 turn set / straight pick-up release

Additional J-slot arrangements available

Product Specifications

Casing | Recommended Hole Size (inches) | Gage OD (inches) | Max OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weight (lbs/ft) | |||||

3-1/2 | 7.7 - 10.2 | 2.922 - 3.068 | 2.781 | - | 1.25 | 1.900 NUE |

4-1/2 | 9.5 - 13.5 | 3.920 - 4.090 | 3.750 | - | 1.94 | 2-3/8 EUE |

13.5 - 15.1 | 3.826 - 3.920 | 3.650 | - | 1.94 | 2-3/8 EUE | |

5 | 11.5 - 15.0 | 4.408 - 4.560 | 4.125 | 4.2201 | 1.94 | 2-3/8 EUE |

5-1/2 | 14.0 - 20.0 | 4.778 - 5.012 | 4.625 | - | 1.94 | 2-3/8 EUE |

- | 2.38 | 2-7/8 EUE | ||||

20.0 - 23.0 | 4.670 - 4.778 | 4.500 | - | 2.00 | 2-3/8 EUE | |

2.38 | 2-7/8 EUE | |||||

5-3/4 | 21.5 - 24.0 | 4.784 - 4.879 | 4.720 | - | 2.38 | 2-7/8 EUE |

6-5/8 | 17.0 - 24.0 | 5.921 - 6.135 | 5.750 | - | 2.50 | 2-7/8 EUE |

24.0 - 32.0 | 5.675 - 5.921 | 5.500 | - | 2.50 | 2-7/8 EUE | |

7 | 17.0 - 26.0 | 6.276 - 6.538 | 6.000 | 6.0621 | 2.50 | 2-7/8 EUE |

6.000 | 6.1251 | 3.00 | 3-1/2 EUE | |||

26.0 - 32.0 | 6.094 - 6.276 | 5.875 | - | 2.50 | 2-7/8 EUE | |

5.9361 | 3.00 | 3-1/2 EUE | ||||

7-5/8 | 24.0 - 29.7 | 6.875 - 7.025 | 6.672 | - | 2.50 | 2-7/8 EUE |

8-5/8 | 28.0 - 40.0 | 7.725 - 8.017 | 7.500 | - | 3.00 | 3-1/2 EUE |

9-5/8 | 32.3 - 43.5 | 8.755 - 9.001 | 8.500 | - | 3.00 | 3-1/2 EUE |

43.5 - 53.5 | 8.535 - 8.755 | 8.250 | - | 2.50 | 2-7/8 EUE | |

- | 4.00 | 4-1/2 EUE | ||||

AS-5 PACKER

The AS-5 Packer is a compression set tool with a J-slot to control pack-off. It is run above other packers - such as the AS-III Packer - to selectively treat, produce or inject in multiple zone completions. It is also used to isolate casing hole perforations. This packer features a large by-pass area to prevent swabbing when running and retrieving. When releasing, the valve allows debris to be washed from the upper slips.

Special Features

Large internal by-pass

Mechanical slips vs. hydraulic buttons

Additional J-slot arrangements available

Product Specification

Casing | Recommended Hole Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weight (lbs/ft) | ||||

4-1/2 | 9.5 - 13.5 | 3.920 - 4.090 | 3.750 | 1.94 | 2-3/8 EUE |

5-1/2 | 14.0 - 20.0 | 4.778 - 5.012 | 4.625 | 2.00 | 2-3/8 EUE |

2.38 | 2-7/8 EUE | ||||

20.0 - 23.0 | 4.670 - 4.778 | 4.500 | 2.00 | 2-3/8 EUE | |

2.38 | 2-7/8 EUE | ||||

7 | 17.0 - 26.0 | 6.276 - 6.538 | 6.000 | 2.50 | 2-7/8 EUE |

3.00 | 3-1/2 EUE | ||||

26.0 - 32.0 | 6.094 - 6.276 | 5.875 | 2.50 | 2-7/8 EUE | |

SNAPSET I PACKER

The Snapset I Packer is a compression set packer requiring only straight set down weight to pack-off. This packer is run above other packers (such as the ASI-X Packer, AS-II Packer or AS-III Packer) for selective production to isolate casing holes and perforations.

This packer has no upper or lower slips and should be used only where intermediate differential pressures from below are expected. This packer has an internal latch to prevent the packer from setting prematurely when running down the hole. When releasing, the latch re-engages to allow movement downhole and re-setting.

Special Features

Large internal by-pass

Set down to pack off, pick up to release

Compact design

Product Specifications

Casing | Recommended Hole Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weight (lbs/ft) | ||||

3-1/2 | 7.7 - 10.2 | 2.922 - 3.068 | 2.781 | 1.25 | 1.900 NUE |

4-1/2 | 9.5 - 13.5 | 3.920 - 4.090 | 3.750 | 1.94 | 2-3/8 EUE |

5-1/2 | 14.0 - 20.0 | 4.778 - 5.012 | 4.625 | 2.00 | 2-3/8 EUE |

2.38 | 2-7/8 EUE | ||||

20.0 - 23.0 | 4.670 - 4.778 | 4.500 | 2.00 | 2-3/8 EUE | |

2.38 | 2-7/8 EUE | ||||

7 | 17.0 - 26.0 | 6.276 - 6.538 | 6.000 | 2.50 | 2-7/8 EUE |

26.0 - 32.0 | 6.094 - 6.276 | 5.875 | 2.50 | 2-7/8 EUE | |

7-5/8 | 24.0 - 29.7 | 6.875 - 7.025 | 6.672 | 2.50 | 2-7/8 EUE |

9-5/8 | 43.5 - 53.5 | 8.535 - 8.755 | 8.250 | 3.00 | 3-1/2 EUE |

SNAPSET II PACKER

The Snapset II Packer is a compression set tool requiring only straight set down weight to pack-off. This packer is run above another compression set packer (such as the AS-III Packer) to selectively treat, produce or inject in multiple zone completions. This packer is also used to isolate casing hole perforations.

This packer features a large by-pass area to prevent swabbing when running and retrieving. Once the packer is set, pressure from above or below acts down on the valve to maintain the seal and prevent upward movement of the tubing.

When releasing, the valve allows debris to be washed from the upper slips. This packer is equipped with an internal latch to prevent setting prematurely when running in the hole. When releasing, the latch re-engages to allow movement downhole.

Special Features

Large internal by-pass

Set down to pack off, pick up to release

Mechanical slips vs. hydraulic buttons

Differential pressure holds valve closed

Product Specifications

Casing | Recommended Hole Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weight (lbs/ft) | ||||

3-1/2 | 7.7 - 10.2 | 2.922 - 3.068 | 2.781 | 1.25 | 1.900 NUE |

4-1/2 | 9.5 - 13.5 | 3.920 - 4.090 | 3.750 | 1.94 | 2-3/8 EUE |

15.1 | 3.826 | 3.656 | 1.94 | 2-3/8 EUE | |

18.8 | 3.640 | 3.437 | 1.50 | 1.900 EUE | |

5 | 11.5 - 15.0 | 4.408 - 4.560 | 4.125 | 1.94 | 2-3/8 EUE |

18.0 - 21.0 | 4.154 - 4.276 | 4.000 | 1.94 | 2-3/8 EUE | |

5-1/2 | 14.0 - 20.0 | 4.778 - 5.012 | 4.625 | 2.00 | 2-3/8 EUE |

2.38 | 2-7/8 EUE | ||||

20.0 - 23.0 | 4.670 - 4.778 | 4.500 | 2.00 | 2-3/8 EUE | |

2.38 | 2-7/8 EUE | ||||

6-5/8 | 24.0 - 32.0 | 5.675 - 5.921 | 5.500 | 2.50 | 2-7/8 EUE |

7 | 17.0 - 26.0 | 6.276 - 6.538 | 6.000 | 2.50 | 2-7/8 EUE |

3.00 | 3-1/2 EUE | ||||

26.0 - 32.0 | 6.094 - 6.276 | 5.875 | 2.50 | 2-7/8 EUE | |

7-5/8 | 24.0 - 29.7 | 6.875 - 7.025 | 6.672 | 2.50 | 2-7/8 EUE |

33.7 - 39.0 | 6.625 - 6.765 | 6.453 | 2.50 | 2-7/8 EUE | |

9-5/8 | 32.3 - 43.5 | 8.755 - 9.001 | 8.500 | 3.00 | 3-1/2 EUE |

CT THERMAL PACKER

The CT Thermal Packer is used in steam injection/production applications. This packer maintains the design features of our reliable ASI-X Packer and includes a packing element that can be packed-off with tension to allow the packer to be set at shallow depth. This packer is capable of setting in shallow wells, and will hold pressure from above and below. Its design also features an adjustable safety shear release.

This packer needs 1/4 right-hand rotation to set it, and 1/4 right-hand rotation to release it (other J-slot designs are available). The thermal elements are available in 450° F to 625° F versions.

An Expansion Joint can be run above this packer to allow for tubing expansion and contraction.

Special Features

1/4 right-hand set, 1/4 right-hand release (standard)

Variable safety shear release

Capable of setting in shallow depths

Holds pressure from above and below

Thermal elements 450° F to 625° F

Additional J-slot arrangements available

Product Specifications

Casing | Recommended Hole Size (inches) | Gage OD (inches) | Max OD (inches) | Min ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weigt (lbs/ft) | |||||

5-1/2 | 13.0 - 17.0 | 4.892 - 5.044 | 4.750 | - | 2.00 | 2-3/8 EUE |

20.0 - 23.0 | 4.670 - 4.778 | 4.500 | - | 2.00 | 2-3/8 EUE | |

6-5/8 | 17.0 - 24.0 | 5.921 - 6.135 | 5.750 | - | 2.50 | 2-7/8 EUE |

24.0 - 32.0 | 5.675 - 5.921 | 5.500 | - | 2.50 | 2-7/8 EUE | |

7 | 17.0 - 26.0 | 6.276 - 6.538 | 6.000 | 6.0621 | 2.50 | 2-7/8 EUE |

3.00 | 3-1/2 EUE | |||||

26.0 - 32.0 | 6.094 - 6.276 | 5.875 | - | 2.50 | 2-7/8 EUE | |

- | 3.00 | 3-1/2 EUE | ||||

IE Thermal Packer

The IE Thermal Packer is a CT Thermal Packer with an Internal Expansion (IE) Joint. This packer is a double-grip retrievable packer designed for steam injection/production. This packer’s design is based on our highly successful ASI-X Packer.

This packer features a double-grip hold down system capable of holding pressure from above and below. This feature allows the packer to maintain pack-off and prevent movement of the packing element without having the packer in tension or compression. The double-grip feature allows the packer to be ideally suited for huff and puff operations as well as continuous steam injection.

This packer is equipped with high temperature EPDM elements with wire mesh backups to prevent extrusion for service up to 450° F (an element package for 650° F is also available).

Special Features

J-Slot controlled expansion joint

Based on proven ASI-X Packer design

Safety shear release

Expansion joint up to 20 Ft available

Product Specifications

Casing | Recommended Hole Size (inches) | Gage OD (inches) | Max OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down | |

Size (inches) | Weight (lbs/ft) | |||||

5 | 11.5 - 15.0 | 4.408 - 4.560 | 4.125 | 42201 | 1.50 | 2-3/8 EUE |

18.0 - 20.8 | 4.156 - 4.276 | 4.000 | - | 1.50 | 2-3/8 EUE | |

7 | 17.0 - 26.0 | 6.276 - 6.538 | 6.000 | 6.1251 | 3.00 | 3-1/2 EUE |

26.0 - 32.0 | 6.094 - 6.276 | 5.875 | - | 3.00 | 3-1/2 EUE | |

9-5/8 | 43.5 - 53.5 | 8.535 - 8.755 | 8.250 | - | 4.00 | 4-1/2 EUE |

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559